- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Working Table Size: | |

|---|---|

| Spindle Motor Power: | |

| Inverter: | |

| Oscillating knife: | |

| Guide rail: | |

| Availability: | |

SOFIA OKC

UTECH

1625 CNC Corrugated Oscillating Vibration Knife Cutter Fabric

Machine with oscillating knife, automatic tool change spindle. Except for EOT-3 oscillating knife for cutting many kinds of soft materials, the spindle also supports the function of CNC router.

Descriptions | Parameters |

Model | UTECH Oscillating Knife + automatic tool change spindle |

Working area | 1300*2500*200mm (can be customized) |

Working Voltage | 220V/380V, 3PHASE, 50HZ (can be customized) |

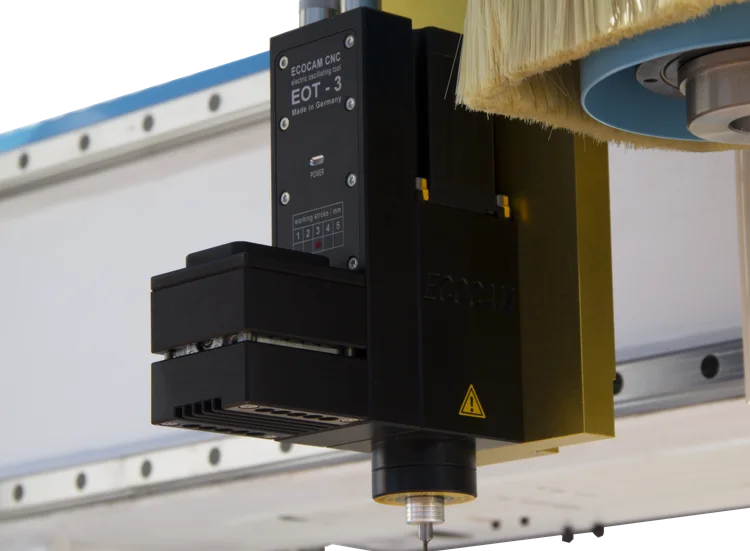

Oscillating knife | Germany ECOCAM EOT-3 |

Visual system | Optional |

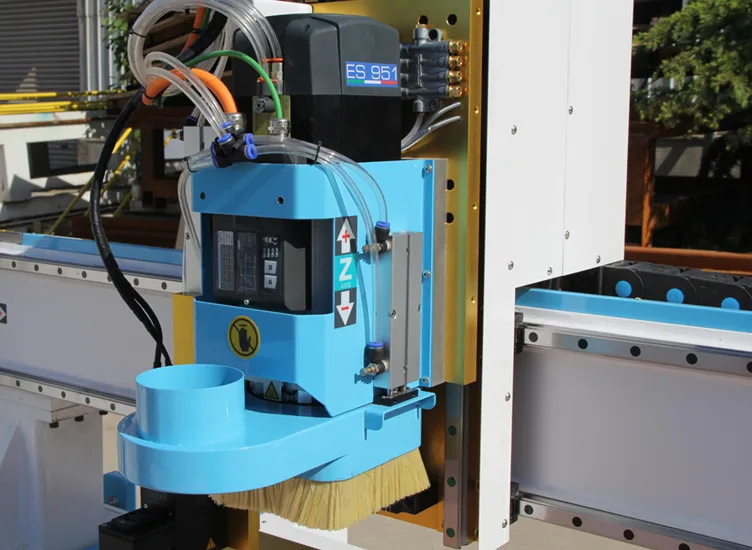

Spindle | HSD ATC 9KW |

Spindle speed | 0-24000RPM |

Motor and Driver | Leadshine hybrid servo motor |

Inverter | 11kw Hpmont inverter |

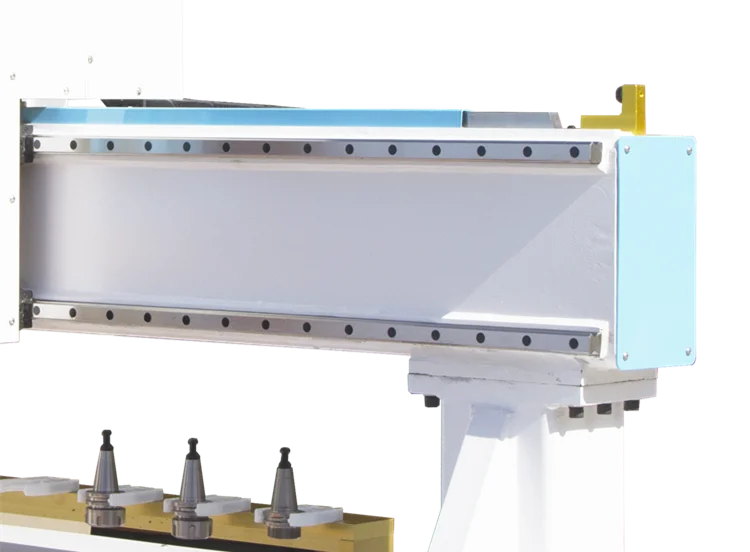

Table surface | T-slot and Vacuum Working Table |

Lubrication system | Automatic lubrication system |

Mist cooling sprayer | Automatic oil mist cooling sprayer(if you process metal) |

Transmission | 1.25M Helical rack, Taiwan Hiwin/PMI 25# Rail Linear Bearing. Z Axis by Taiwan TBI Ball Screw Whole machine with Japan SHIMPO reducer 1:5 |

Dust Collector | Binocular or monocular dust collector(Optional) |

Machining Accuracy | ±0.2mm |

Repositioning Resolution | ±0.01mm |

Machine features

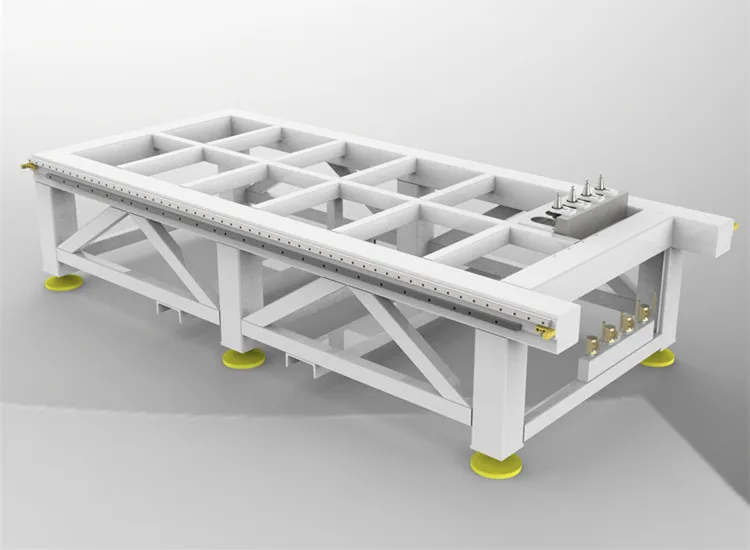

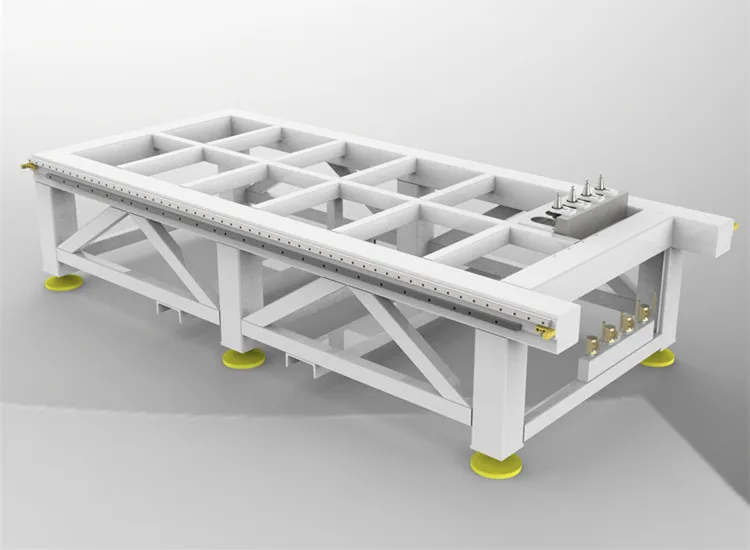

1. The bed is made of high-rigidity rectangular steel pipe welded and optimized dragnet structure, aging treatment to ensure the precision of the bed.

2. Double heads device--spindle and oscillating knife, can be cut according to different materials. After many improved tests, we update machine, now machine only have one Z axis for spindle and oscillating knife, it’s integrated together to share one z-axis motor&drive, and doesn’t need another set of motor&driver to control the z-axis of oscillating knife separately.

3. Excellent visual positioning system, one-click cutout and one-click start processing, free of typesetting&cutout time, improve processing efficiency. Equipped with professional 1.5 megapixel industrial camera, powerful image recognition, more accurate cutting.

4. Oscillating knife head can be processed and tracing-edge cutting according to different materials, the material dust-free and without raw edge.

5. CCD: Tracing-edge cutting for different materials, KT board, PVC, photo paper to achieve no burr cutting.

6. Transmission model adopt precision reducer match with brand gear rack, large torque, low noise and high transmission precision accuracy.

7. Machine supports DXF, JPG, PNG, NC and other formats, not only with automatic tracing-edge, but also support the function of CNC router.

Component features

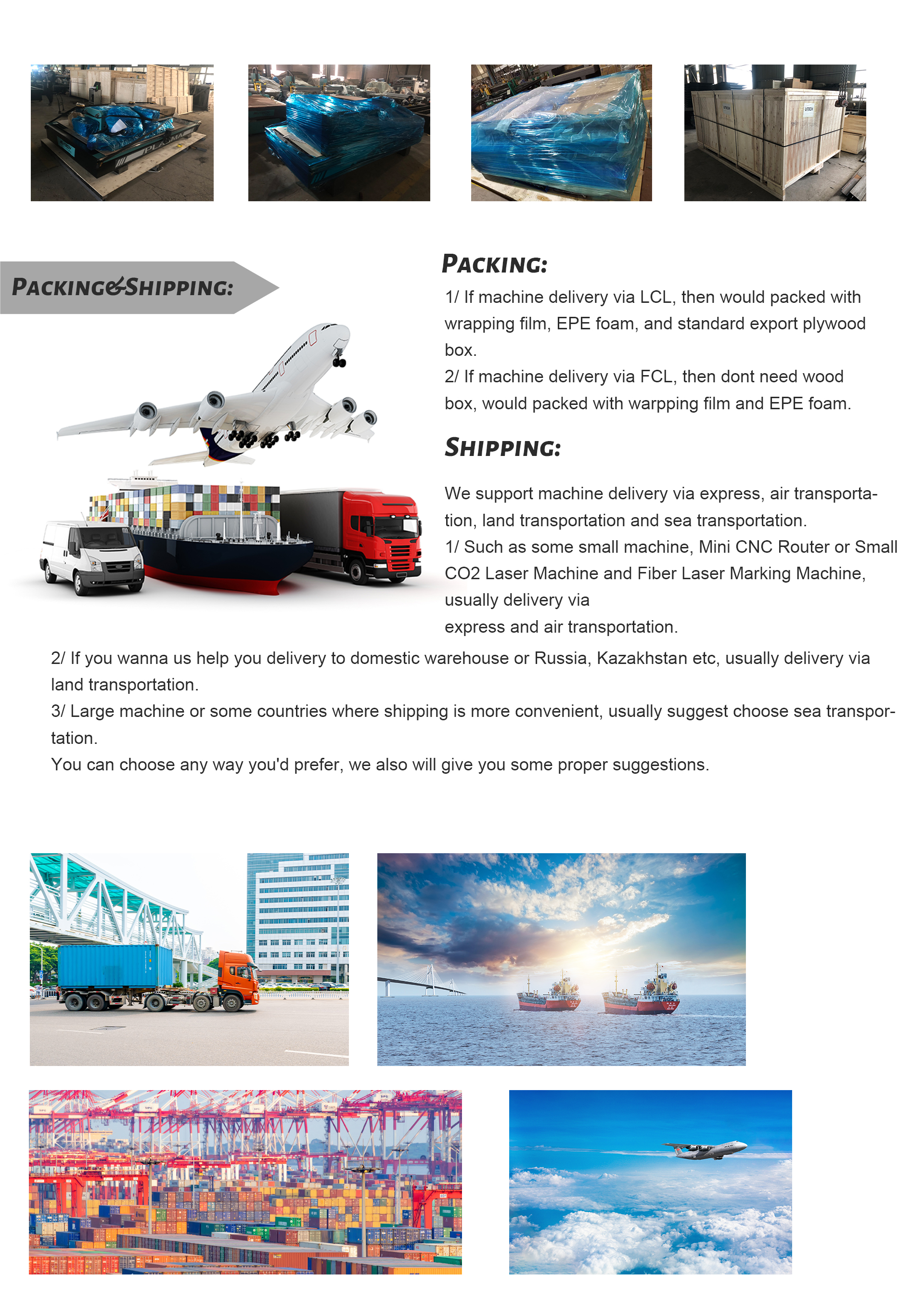

CNC-machined, rugged metal housing

Precision kinematics

Oscillation frequency: approx. 3500 –7000 stroke per minute (12-20VDC)

Drive motor with multiple ball bearings

Opto-electronic, contactless detection of the blade position

Equipped with a reverse polarity protection and an optical display for the working status

Internal voltage regulator and stabilizer

Equipped with a signal amplifier that generates a clearly defined digital signal for the reference position of the tangential axis.

High compatibility with equipment from different manufacturers

HUB 3mm is sold in 95% of the applications

HUB 5mm is only for special materials(long stroke) wear is higher

2-phase high-torque stepper motor with a full step angle of 0.9° (= 400 steps per revolution) ensures precise positioning and strong holding force

Weight: approx 2.5 kg

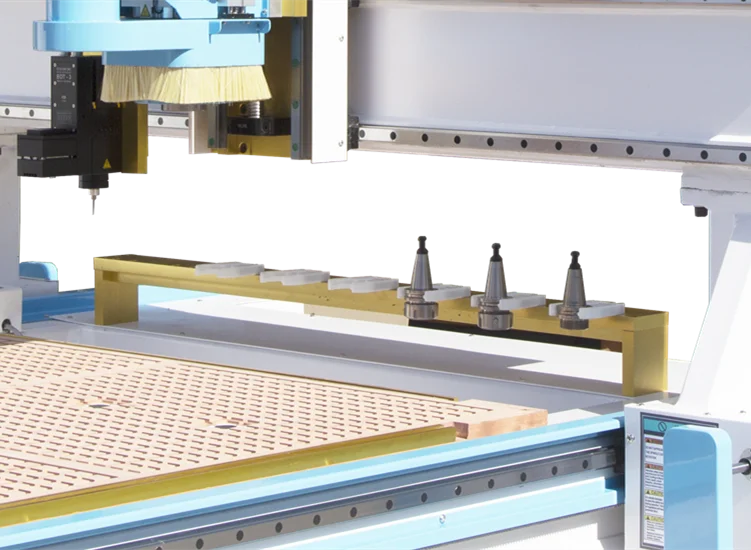

EOT-3 - Oscillating Knife The EOT-3 is a processing unit. A powerful oscillation motor moves the blade quickly up and down while an actuator rotates the blade in each direction of cutting. Thus, even strong and thick materials can be cut precisely and quickly. |  |

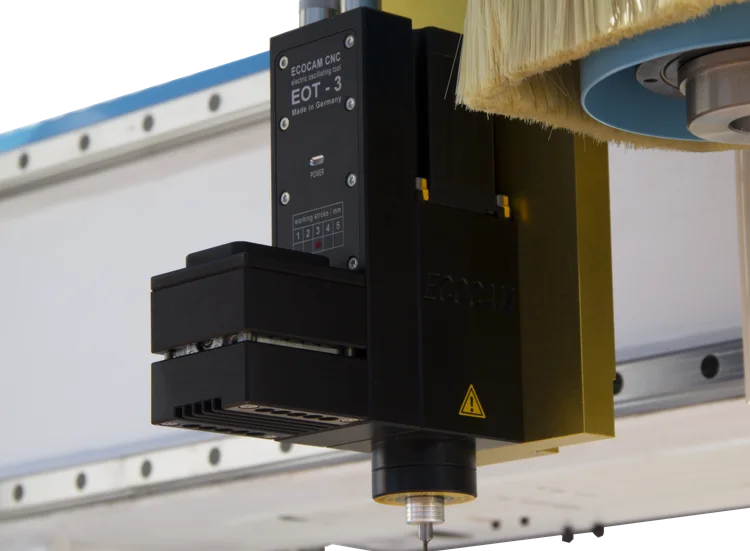

| HSD 9KW ATC spindle Industry leader in wood, aluminum and plastics processing |

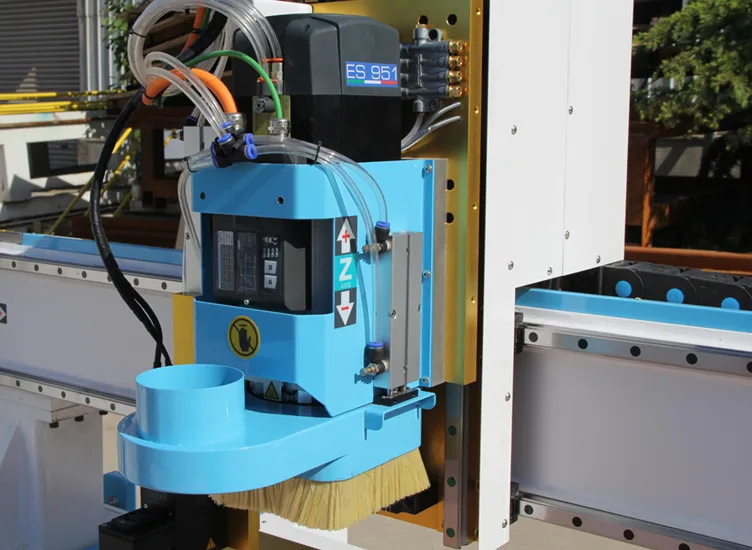

Linear tool 6 pcs For maximum productivity, the machine can be fitted with an automatic tool change carousel type/Linear tools type 4, 8 or even 16 tool stations. |  |

| XINGDUOWEI control system Network cable transmission, no need to insert card, no need for frequent take-off and landing knife. |

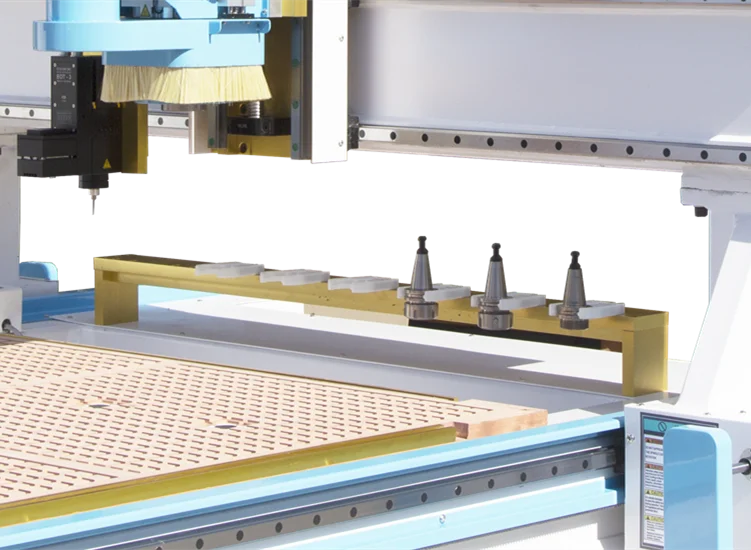

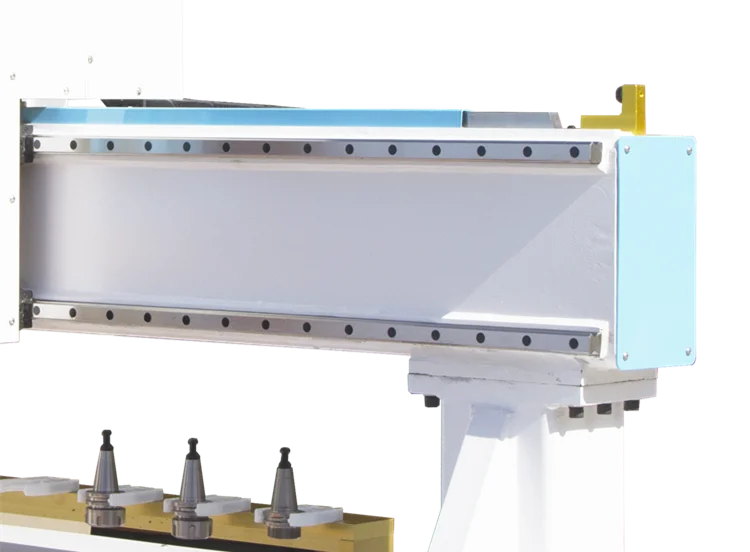

Taiwan square rail Choose heavy duty linear guide rail with high assembly Flange sliding block and PMI linear guide. The Y-axis adopts double-row four-column guide rail, with strong bearing force, fast speed, smooth operation, high precision and high life span. |  |

| Taiwan square rail Choose heavy duty linear guide rail with high assembly Flange sliding block and PMI linear guide. The Y-axis adopts double-row four-column guide rail, with strong bearing force, fast speed, smooth operation, high precision and high life span. |

1625 CNC Corrugated Oscillating Vibration Knife Cutter Fabric

Machine with oscillating knife, automatic tool change spindle. Except for EOT-3 oscillating knife for cutting many kinds of soft materials, the spindle also supports the function of CNC router.

Descriptions | Parameters |

Model | UTECH Oscillating Knife + automatic tool change spindle |

Working area | 1300*2500*200mm (can be customized) |

Working Voltage | 220V/380V, 3PHASE, 50HZ (can be customized) |

Oscillating knife | Germany ECOCAM EOT-3 |

Visual system | Optional |

Spindle | HSD ATC 9KW |

Spindle speed | 0-24000RPM |

Motor and Driver | Leadshine hybrid servo motor |

Inverter | 11kw Hpmont inverter |

Table surface | T-slot and Vacuum Working Table |

Lubrication system | Automatic lubrication system |

Mist cooling sprayer | Automatic oil mist cooling sprayer(if you process metal) |

Transmission | 1.25M Helical rack, Taiwan Hiwin/PMI 25# Rail Linear Bearing. Z Axis by Taiwan TBI Ball Screw Whole machine with Japan SHIMPO reducer 1:5 |

Dust Collector | Binocular or monocular dust collector(Optional) |

Machining Accuracy | ±0.2mm |

Repositioning Resolution | ±0.01mm |

Machine features

1. The bed is made of high-rigidity rectangular steel pipe welded and optimized dragnet structure, aging treatment to ensure the precision of the bed.

2. Double heads device--spindle and oscillating knife, can be cut according to different materials. After many improved tests, we update machine, now machine only have one Z axis for spindle and oscillating knife, it’s integrated together to share one z-axis motor&drive, and doesn’t need another set of motor&driver to control the z-axis of oscillating knife separately.

3. Excellent visual positioning system, one-click cutout and one-click start processing, free of typesetting&cutout time, improve processing efficiency. Equipped with professional 1.5 megapixel industrial camera, powerful image recognition, more accurate cutting.

4. Oscillating knife head can be processed and tracing-edge cutting according to different materials, the material dust-free and without raw edge.

5. CCD: Tracing-edge cutting for different materials, KT board, PVC, photo paper to achieve no burr cutting.

6. Transmission model adopt precision reducer match with brand gear rack, large torque, low noise and high transmission precision accuracy.

7. Machine supports DXF, JPG, PNG, NC and other formats, not only with automatic tracing-edge, but also support the function of CNC router.

Component features

CNC-machined, rugged metal housing

Precision kinematics

Oscillation frequency: approx. 3500 –7000 stroke per minute (12-20VDC)

Drive motor with multiple ball bearings

Opto-electronic, contactless detection of the blade position

Equipped with a reverse polarity protection and an optical display for the working status

Internal voltage regulator and stabilizer

Equipped with a signal amplifier that generates a clearly defined digital signal for the reference position of the tangential axis.

High compatibility with equipment from different manufacturers

HUB 3mm is sold in 95% of the applications

HUB 5mm is only for special materials(long stroke) wear is higher

2-phase high-torque stepper motor with a full step angle of 0.9° (= 400 steps per revolution) ensures precise positioning and strong holding force

Weight: approx 2.5 kg

EOT-3 - Oscillating Knife The EOT-3 is a processing unit. A powerful oscillation motor moves the blade quickly up and down while an actuator rotates the blade in each direction of cutting. Thus, even strong and thick materials can be cut precisely and quickly. |  |

| HSD 9KW ATC spindle Industry leader in wood, aluminum and plastics processing |

Linear tool 6 pcs For maximum productivity, the machine can be fitted with an automatic tool change carousel type/Linear tools type 4, 8 or even 16 tool stations. |  |

| XINGDUOWEI control system Network cable transmission, no need to insert card, no need for frequent take-off and landing knife. |

Taiwan square rail Choose heavy duty linear guide rail with high assembly Flange sliding block and PMI linear guide. The Y-axis adopts double-row four-column guide rail, with strong bearing force, fast speed, smooth operation, high precision and high life span. |  |

| Taiwan square rail Choose heavy duty linear guide rail with high assembly Flange sliding block and PMI linear guide. The Y-axis adopts double-row four-column guide rail, with strong bearing force, fast speed, smooth operation, high precision and high life span. |

Germany ECOCAM EOT-3 Oscillating Knife cutting machine applies for shoes making industry, apparel and fashion cloth industry, automotive interior industry, luggage industry, package industry, decoration industry, electronic industry, composite materials industry etc.

It can process fabric, knitting vamps, non-woven, leather, rexine, cotton, felt, silk, lace, polyester, fleece, soft shell, jeans, alcantara, neoprene, corrugated board, cardboard, white board, gray board, sticker, PVC film, foam board, artificial leather, leather, gasket, sponge, prepreg, acrylic, honeycomb board, fiberboard, epoxy resin board, organic glass, car mat, fiber, composite material and other soft materials, etc

cnc router spindle

Wood working: Solid wave board process,door of cabinet,wooden door,artistic wooden door ,no-paint door, avoid wind, process of the artistic window,shoes cleaning machine,the cabinet of the playing machine and the board,mahjong table, computer table and the assistant process of the household effect.

Advertising: Advertising board,Label design,Acrylic cutting,model, of the multi material decoration products.

Model industry: It can engrave on the steal materials such as copper, aluminum ,iron etc and non-mental materials such as man-made marble, sand, plastic board PVC materials, wood board etc.

Other fields: It can engrave many image, engrossment,It is widely used in artistic industry.

Germany ECOCAM EOT-3 Oscillating Knife cutting machine applies for shoes making industry, apparel and fashion cloth industry, automotive interior industry, luggage industry, package industry, decoration industry, electronic industry, composite materials industry etc.

It can process fabric, knitting vamps, non-woven, leather, rexine, cotton, felt, silk, lace, polyester, fleece, soft shell, jeans, alcantara, neoprene, corrugated board, cardboard, white board, gray board, sticker, PVC film, foam board, artificial leather, leather, gasket, sponge, prepreg, acrylic, honeycomb board, fiberboard, epoxy resin board, organic glass, car mat, fiber, composite material and other soft materials, etc

cnc router spindle

Wood working: Solid wave board process,door of cabinet,wooden door,artistic wooden door ,no-paint door, avoid wind, process of the artistic window,shoes cleaning machine,the cabinet of the playing machine and the board,mahjong table, computer table and the assistant process of the household effect.

Advertising: Advertising board,Label design,Acrylic cutting,model, of the multi material decoration products.

Model industry: It can engrave on the steal materials such as copper, aluminum ,iron etc and non-mental materials such as man-made marble, sand, plastic board PVC materials, wood board etc.

Other fields: It can engrave many image, engrossment,It is widely used in artistic industry.

Packing:

1/ If machine delivery via LCL, then would packed with wrapping film, EPE foam, and standard export plywood box.

2/ If machine delivery via FCL, then dont need wood box, would packed with warpping film and EPE foam.

Shipping:

We support machine delivery via express, air transportation, land transportation and sea transportation.

1/ Such as some small machine, Mini CNC Router or Small CO2 Laser Machine and Fiber Laser Marking Machine, usually delivery via express and air transportation.

2/ If you wanna us help you delivery to domestic warehouse or Russia, Kazakhstan etc, usually delivery via land transportation.

3/ Large machine or some countries where shipping is more convenient, usually suggest choose sea transportation.

You can choose any way you'd prefer, we also will give you some proper suggestions.

Packing:

1/ If machine delivery via LCL, then would packed with wrapping film, EPE foam, and standard export plywood box.

2/ If machine delivery via FCL, then dont need wood box, would packed with warpping film and EPE foam.

Shipping:

We support machine delivery via express, air transportation, land transportation and sea transportation.

1/ Such as some small machine, Mini CNC Router or Small CO2 Laser Machine and Fiber Laser Marking Machine, usually delivery via express and air transportation.

2/ If you wanna us help you delivery to domestic warehouse or Russia, Kazakhstan etc, usually delivery via land transportation.

3/ Large machine or some countries where shipping is more convenient, usually suggest choose sea transportation.

You can choose any way you'd prefer, we also will give you some proper suggestions.