- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Spindle Motor: | |

|---|---|

| Driving System: | |

| Table Structure: | |

| Control system: | |

| Availability: | |

Sesame

UTECH

UT-1325

SESAME 4.5kw air cooled spindle cnc router machine for simple wood industry

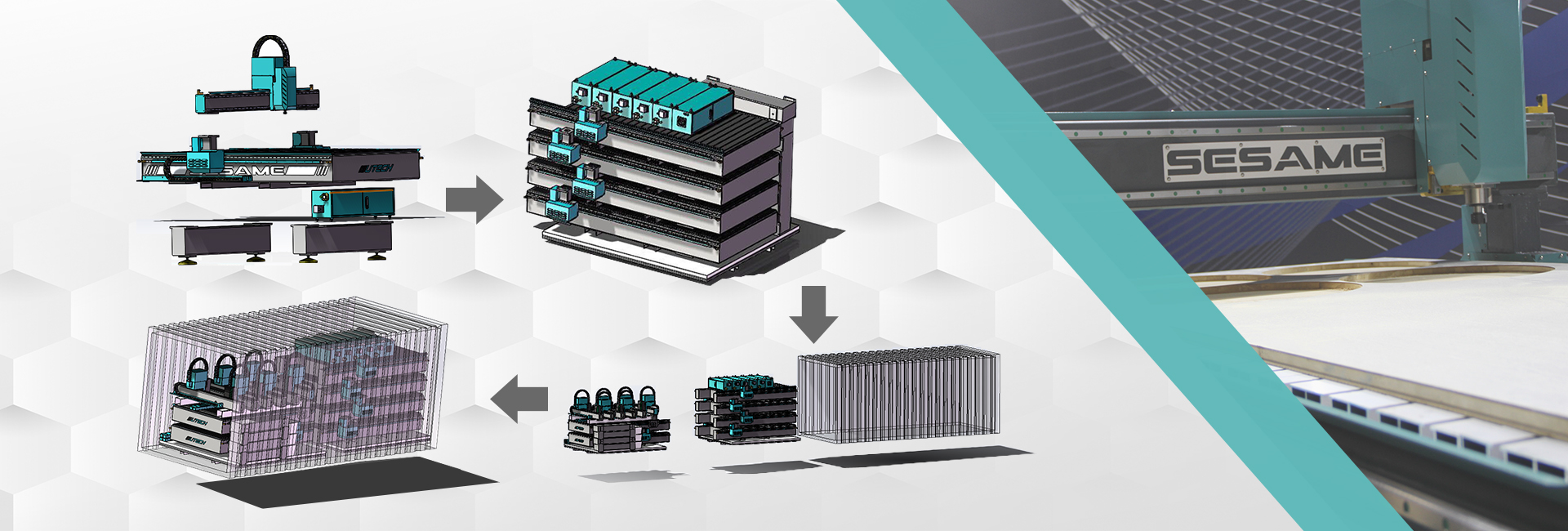

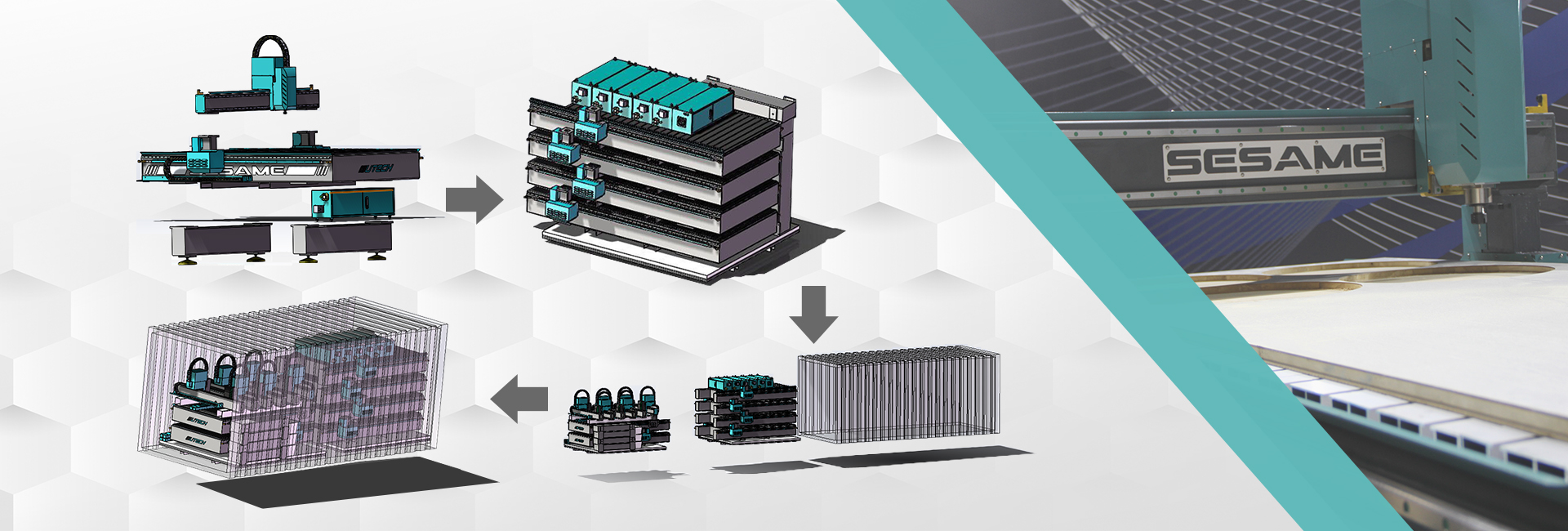

One wood box: 2/3 sets SESAME 1325

One container: 6 sets SESAME 1325

![]() Description:

Description:

Our SESAME model is the precise investment for your company, this model as an entry-level device, is presented with a very low price and industrial benefits so that your enterprise can grow and reach the next level that we know you are looking for.

The SESAME CNC Router’s greatest advantage is machine lathe bed and legs could be split freely, accoding to customer’s request, can choose to disassemble the machine when shipping, which could save space and shipping cost. In such a severe international situation, harsh conditions such as difficulty in booking space and rising freight rates have severely hindered the transportation of goods and the normal operation and development of enterprises. SESAME’s disassembly advange would be a shining point in the near future. The UTECH team has tested and implemented many loading and unloading solutions, such as 2/3 machines to pack a same wooden box; a 20GP container to package 6 sets SESAME 1325, a 40HQ container to package 20 sets SESAME 1325, etc.

Before the machine leaves the factory, each machine will undergo rigorous testing. You can leave the factory only after reaching the standard, and you will get a perfect device that can be used directly. And we provide local services, such as the United States, Mexico, Peru, France, Spain, Romania and other countries.

As the epidemic situation is getting more and more severe today, the UTECH team will do everything possible to overcome all difficulties for you.

![]() Details:

Details:

Descriptions | SESAME CNC Router | |||

Model | UT-1530 | UT-2141 | Support customized | |

Working area | 1300*2500mm | 1500*3000mm | 2100*4100mm | any size |

Accuracy | ±0.02mm | |||

Table Surface | Vacuum/T-slot table OR Double table | |||

Frame | Square pipe welding bed structure 200*300mm+150*200mm gantry | |||

X, Y Structure | 1.25M Helical gear rack transmission, Taiwan Linear Rail Guide | |||

Z Structure | Taiwan TBI Ball Screw, Taiwan Linear Rail Guide | |||

Spindle Power | 4.5kw air cooled spindle+ER25 cutter | |||

Spindle Speed | 18000-24000RPM | |||

Drive Motors | JMC stepper motor and driver+UTECH patent typre reducer | |||

Working Voltage | 220/380V | |||

Command Language | G Code | |||

Operating System | HD100 handle controller (DSP or Mach3 optional) | |||

Computer Interface | Ethernet (or USB) | |||

Dust Collector | 2.2kw/3kw | |||

Inverter | Best | |||

Software | Vectric Aspire/Type 3 /Artcam /Ucancam/JDPaint | |||

![]() Advantages:

Advantages:

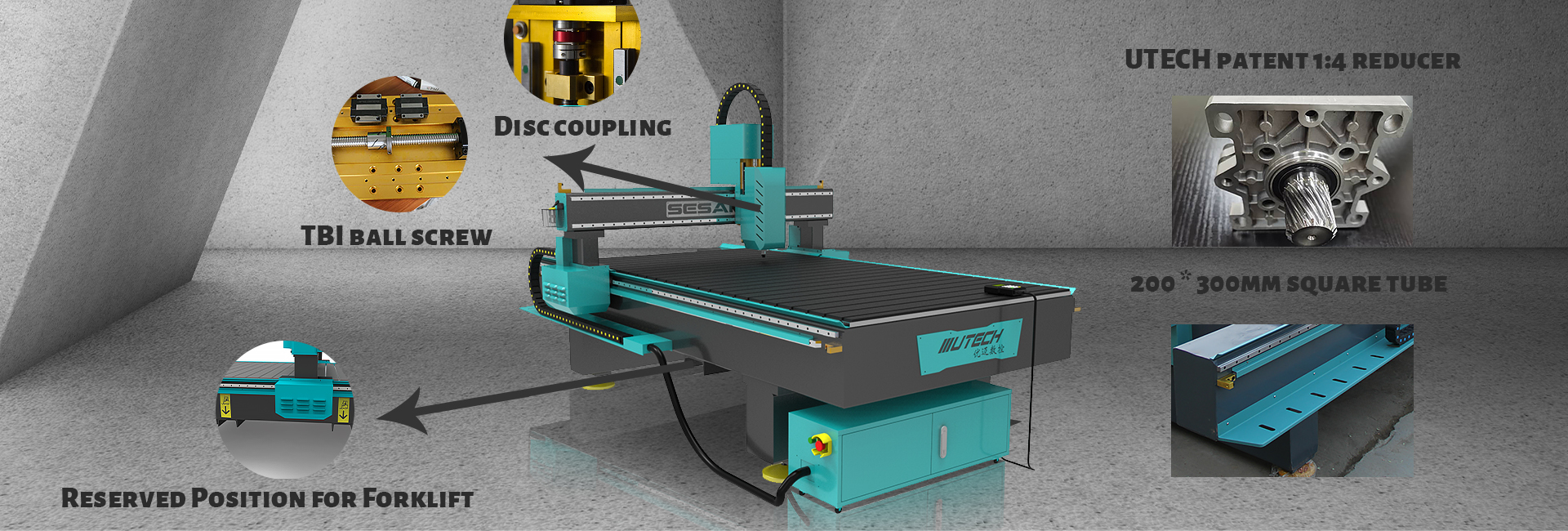

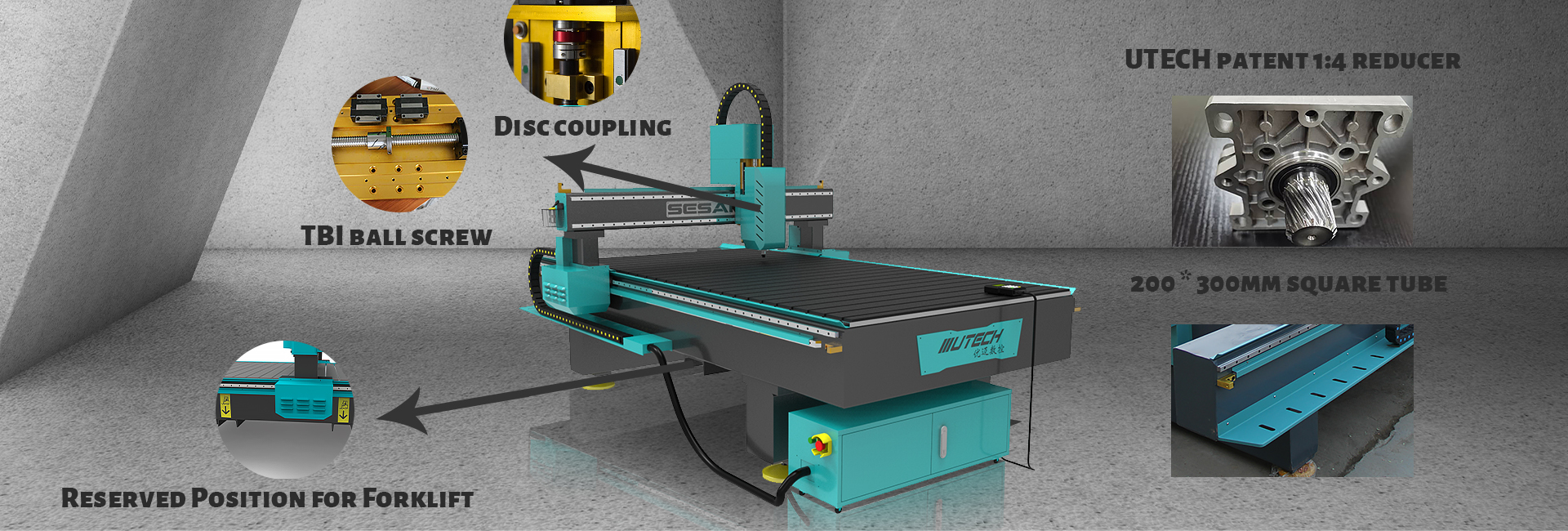

1. Machine bed

Machine bed with 200 * 300mm square tube welded together, compared to ordinary machines, we use the square tube model can better reflect the stability of the equipment.

2. Reserved Position for Forklift

Bed welding process increases the reserved forklift, highlights two major advantages: First, increase the strength of the bed itself; Second, it`s more convenient for customers to load or unload the equipment.

3. Transmission stand column

Transmission stand column, we adopt high precision machining process, ensure the accuracy of accessories. Like insert cavity position, assembly surface.

4. SESAME machine head

First, For the choice of hand piece, we choose T6061/6063 aviation aluminum alloy as the base material. Through the precision processing of CNC Processing Center, we finished our finished parts. Second, the high requirement assembly process ensures the precision of the product.

5. Unpacking saves transportation costs+Patent design transmission structure.

6. Optimize the design structure to facilitate the customer fork handling equipment, reserved for forklift special seats.

7. SESEMA adopt portable optimized design small separate control cabinet.

![]() Service:

Service:

UTECH has a professional design and technical team to meet all your needs, and the equipment supports customization.

Before confirming the production order, we will provide the rendering picture and 360-degree panoramic video, so that customers can fully understand the style and structure of the machine, so as to ensure that the actual machine meets the requirements of customers, so as to avoid the discrepancy between the real object and customers' imagination caused by various communication deviations.

UTECH technical support is designed to help you make the most of the machine. A variety of technical files and installation videos will be placed in the U disk and shipped with the machine. Our technical experts can provide online remote support and training, and contact UTECH technical support experts in real-time for remote diagnosis. Door-to-door service is also available.

![]() Applications:

Applications:

WoodFurniture Industry: Wave Plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates,cupboarddoors, interior doors, sofa legs, headboards and so on.

Advertising Industry: advertising identification, sigh making, Acrylic engraving and cutting, crystal word making,blaster molding,and other advertising materials derivatives making.

SESAME 4.5kw air cooled spindle cnc router machine for simple wood industry

One wood box: 2/3 sets SESAME 1325

One container: 6 sets SESAME 1325

![]() Description:

Description:

Our SESAME model is the precise investment for your company, this model as an entry-level device, is presented with a very low price and industrial benefits so that your enterprise can grow and reach the next level that we know you are looking for.

The SESAME CNC Router’s greatest advantage is machine lathe bed and legs could be split freely, accoding to customer’s request, can choose to disassemble the machine when shipping, which could save space and shipping cost. In such a severe international situation, harsh conditions such as difficulty in booking space and rising freight rates have severely hindered the transportation of goods and the normal operation and development of enterprises. SESAME’s disassembly advange would be a shining point in the near future. The UTECH team has tested and implemented many loading and unloading solutions, such as 2/3 machines to pack a same wooden box; a 20GP container to package 6 sets SESAME 1325, a 40HQ container to package 20 sets SESAME 1325, etc.

Before the machine leaves the factory, each machine will undergo rigorous testing. You can leave the factory only after reaching the standard, and you will get a perfect device that can be used directly. And we provide local services, such as the United States, Mexico, Peru, France, Spain, Romania and other countries.

As the epidemic situation is getting more and more severe today, the UTECH team will do everything possible to overcome all difficulties for you.

![]() Details:

Details:

Descriptions | SESAME CNC Router | |||

Model | UT-1530 | UT-2141 | Support customized | |

Working area | 1300*2500mm | 1500*3000mm | 2100*4100mm | any size |

Accuracy | ±0.02mm | |||

Table Surface | Vacuum/T-slot table OR Double table | |||

Frame | Square pipe welding bed structure 200*300mm+150*200mm gantry | |||

X, Y Structure | 1.25M Helical gear rack transmission, Taiwan Linear Rail Guide | |||

Z Structure | Taiwan TBI Ball Screw, Taiwan Linear Rail Guide | |||

Spindle Power | 4.5kw air cooled spindle+ER25 cutter | |||

Spindle Speed | 18000-24000RPM | |||

Drive Motors | JMC stepper motor and driver+UTECH patent typre reducer | |||

Working Voltage | 220/380V | |||

Command Language | G Code | |||

Operating System | HD100 handle controller (DSP or Mach3 optional) | |||

Computer Interface | Ethernet (or USB) | |||

Dust Collector | 2.2kw/3kw | |||

Inverter | Best | |||

Software | Vectric Aspire/Type 3 /Artcam /Ucancam/JDPaint | |||

![]() Advantages:

Advantages:

1. Machine bed

Machine bed with 200 * 300mm square tube welded together, compared to ordinary machines, we use the square tube model can better reflect the stability of the equipment.

2. Reserved Position for Forklift

Bed welding process increases the reserved forklift, highlights two major advantages: First, increase the strength of the bed itself; Second, it`s more convenient for customers to load or unload the equipment.

3. Transmission stand column

Transmission stand column, we adopt high precision machining process, ensure the accuracy of accessories. Like insert cavity position, assembly surface.

4. SESAME machine head

First, For the choice of hand piece, we choose T6061/6063 aviation aluminum alloy as the base material. Through the precision processing of CNC Processing Center, we finished our finished parts. Second, the high requirement assembly process ensures the precision of the product.

5. Unpacking saves transportation costs+Patent design transmission structure.

6. Optimize the design structure to facilitate the customer fork handling equipment, reserved for forklift special seats.

7. SESEMA adopt portable optimized design small separate control cabinet.

![]() Service:

Service:

UTECH has a professional design and technical team to meet all your needs, and the equipment supports customization.

Before confirming the production order, we will provide the rendering picture and 360-degree panoramic video, so that customers can fully understand the style and structure of the machine, so as to ensure that the actual machine meets the requirements of customers, so as to avoid the discrepancy between the real object and customers' imagination caused by various communication deviations.

UTECH technical support is designed to help you make the most of the machine. A variety of technical files and installation videos will be placed in the U disk and shipped with the machine. Our technical experts can provide online remote support and training, and contact UTECH technical support experts in real-time for remote diagnosis. Door-to-door service is also available.

![]() Applications:

Applications:

WoodFurniture Industry: Wave Plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates,cupboarddoors, interior doors, sofa legs, headboards and so on.

Advertising Industry: advertising identification, sigh making, Acrylic engraving and cutting, crystal word making,blaster molding,and other advertising materials derivatives making.