- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Cutting Area: | |

|---|---|

| Structure: | |

| X, Y axis transmission: | |

| Table structure: | |

| Availability: | |

SESAME-ATC

UTECH

4axis ATC cnc machine with Drilling Head

Precision, efficiency, and versatility - this is the promise of our 4axis ATC cnc machine with Drilling Head. This machine brings unprecedented productivity and creative freedom to the woodworking industry. Whether it is complex engraving tasks or precise hole processing, it can easily handle it. Its advanced automatic tool change system and multi-functional drilling head make it an ideal choice for the fields of woodworking and metalworking. Whether you are pursuing productivity or exquisite craftsmanship, our machine tools can provide you with excellent performance and reliable operating experience.

Main features include:

4-axis processing capability: provides more processing freedom and multi-angle operation, suitable for complex 3D engraving and stereo processing.

Automatic tool change system (ATC): equipped with advanced automatic tool change system, no manual tool change is required, fast and accurate tool change is achieved, and production efficiency is improved.

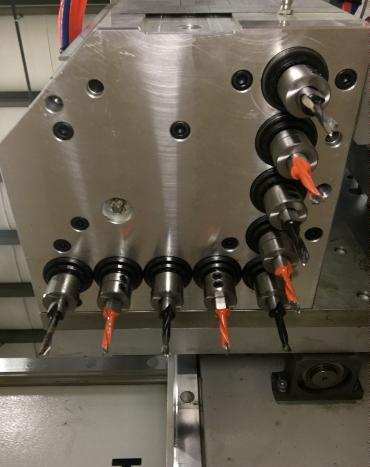

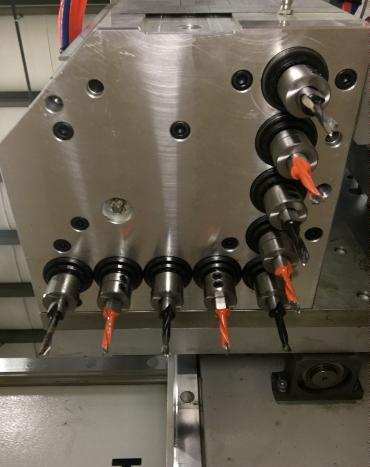

Multi-functional drilling head: integrates multiple functions such as drilling and boring, suitable for various processing needs, from simple hole processing to complex positioning hole operations.

High precision and stability: adopts high-quality guide rails and stable machine tool structure to ensure high-precision processing quality and long-term stable operation.

Choose our 4axis ATC cnc machine with Drilling Head to make your processing more efficient and precise, and achieve a wider range of applications and greater production potential. Contact us now for more details and customization options!

Product Parameters

| Product name | 4axis ATC cnc machine with Drilling Head |

| Working area | 1500*mm*3000mm*300mm |

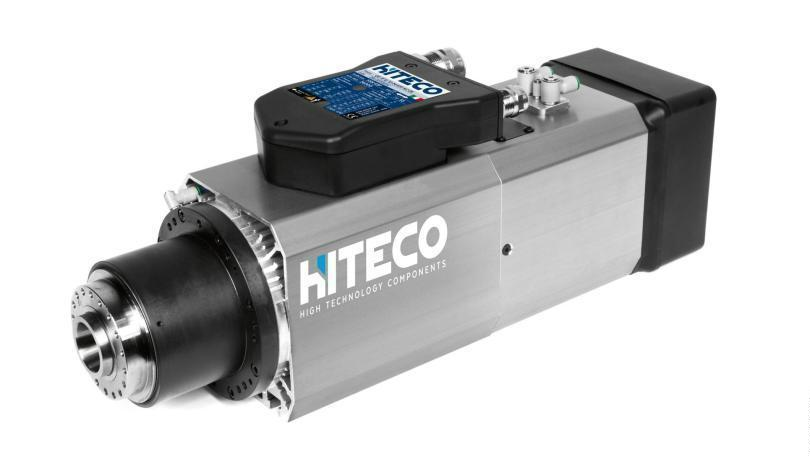

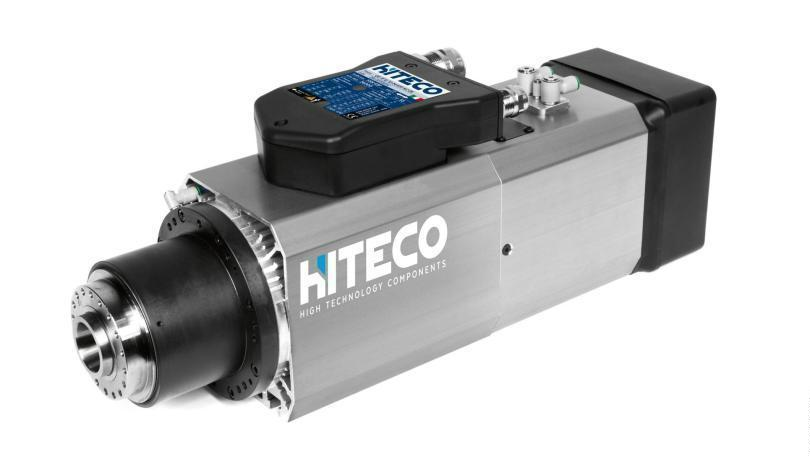

| Spindle power | 9KW HITECO Spindle Head + HITECO Twin Double Aggregate Head + HSD 5+4 Drill Block + 4 Axis Rotary Axis |

| Controller | Syntec 60E Control System |

| Motor&driver | Yaskawa 1000W Servo Motor And Driver*4 |

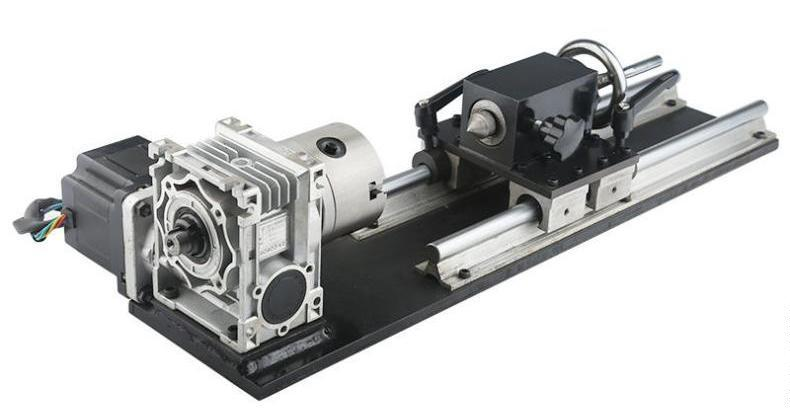

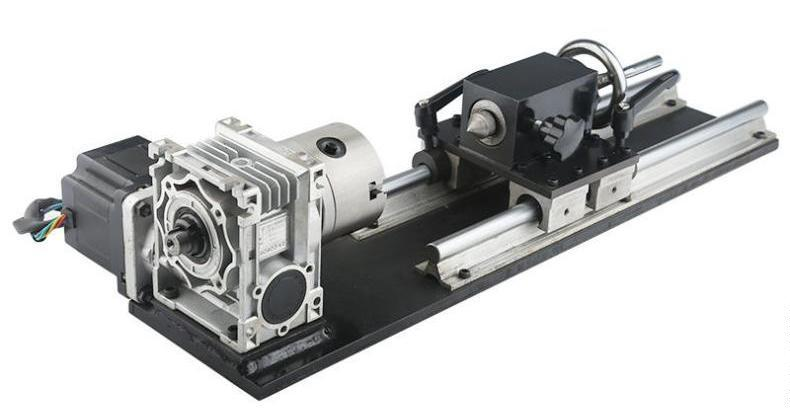

| Transmission | Precision Taiwan JINGTE Helical gear rack +Three sets Japan SHIMPO reducer1:10 |

| Rail guide | XY axis by J&T 1.5M helical gear rack transmission, Z axis by Taiwan TBI ball screw |

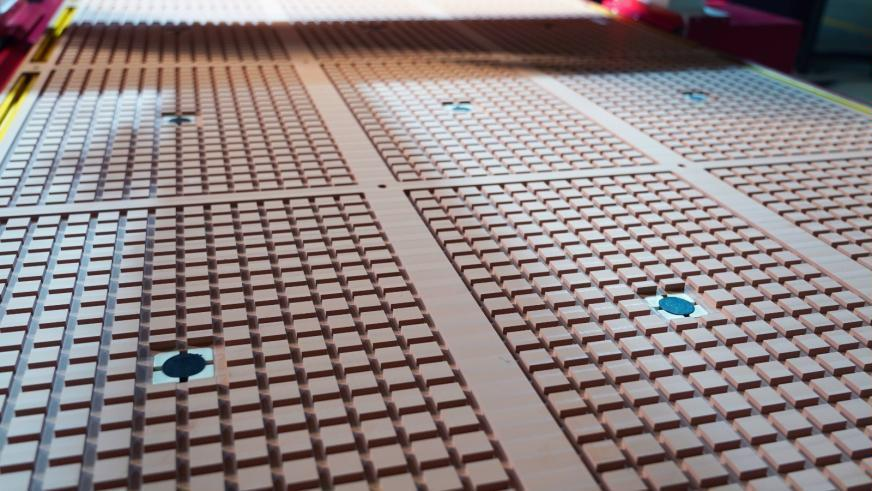

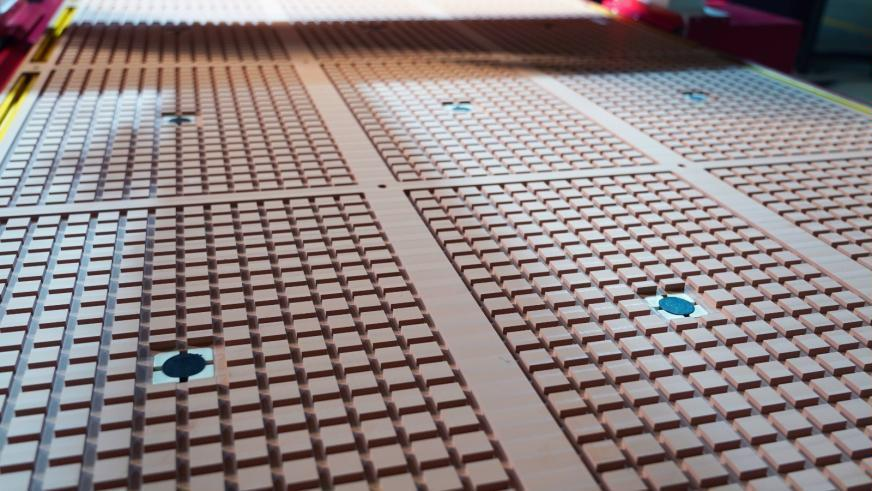

| Table | Vacuum and T-slot Table |

| Machining Accuracy | ±0.1mm |

| Repositioning Resolution | ±0.01mm |

| Rotary Axis | 200mm Diameter, 1500mm length |

Product Details

Spindle ( HITECO Double Head Aggregate Head )

Control system (New Generation 60E control system)

Drive Motor (Yaskawa 1000W Servo Motors )

A Axis Rotary ( 200mm x 1500mm)

Dust Collection System ( ISO 30 8 Tool Magazine)

Countertop Structure ( Vacuum Table )

Vacuum Pump ( 2.2kw Vacuum Pump )

Oiling System ( Automatic Oiling System )

Guard Rail ( Taiwan HIWIN )

Reducer ( Japan Shinpo Reducer )

Spindle Head ( 9KWK HITECO Spindle Head )

Drill Block ( HSD5 +4 Drill Block )

Product Advantages

Application of 4axis ATC cnc machine with Drilling Head

CNC Routers such as the 4axis ATC Cnc Machine with Drilling Head can be used in many different applications such as:

1. Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors, and windows.

2. Wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

3. Plate processing: insulation part, plastic chemical components, PCB, inner body of the car, bowling tracks, stairs, anti-bate board, epoxy resin, ABS, PP, PE, and other carbon mixed compounds.

4. Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic, and soft metals such as copper, aluminum plate engraving, and milling process.

FAQ

Linear Tool Changer & Carousel Tool Changer

The linear tool magazine can be placed under the gantry or behind the machine. The linear tool change usually could be support 4-10 pcs tool holder, and the additional space is limited. The carousel tool magazine can be installed on the side or top of the gantry, or as an independent part outside the machine. A variety of tools for different purposes can be clamped, such as 8, 12, 16, 20 tools, etc., and different processing procedures can be completed through automatic tool change controlled by the CNC system.

The carousel tool changer machining center is more suitable for door panel processing. If you need to use this model for cabinet drilling, slotting and cutting, due to the weight of the gantry, plus a series of accessories such as the spindle and tool magazine, it will affect For the operating speed of the machine, the door panel requires precision. The demand for speed is not as large as the cabinet body. However, the cabinet body processing requires both accuracy and speed. The carousel tool changer can be used to process the cabinet body, but it is not suitable for processing the cabinet body. The linear tool changer machining center is a bit more suitable than the carousel tool change, and it can fully meet the precision and speed required by the cabinet and door panel processing. Moreover, this model of the straight row tool change machining center is more suitable for substituting machining, cabinets, Door panels, embossments, hollows, and lattices can guarantee the processing volume within the production capacity.

Compared with the linear tool changer, the carousel tool change machining center has a higher cost, but the machining accuracy and stability of the carousel tool change machining center will be guaranteed, and the long-term use effect will not be affected.

According to your budget, equipment requirements and processing needs, you can choose the right style. If you don't know how to choose, UTECH will help you.

4axis ATC cnc machine with Drilling Head

Precision, efficiency, and versatility - this is the promise of our 4axis ATC cnc machine with Drilling Head. This machine brings unprecedented productivity and creative freedom to the woodworking industry. Whether it is complex engraving tasks or precise hole processing, it can easily handle it. Its advanced automatic tool change system and multi-functional drilling head make it an ideal choice for the fields of woodworking and metalworking. Whether you are pursuing productivity or exquisite craftsmanship, our machine tools can provide you with excellent performance and reliable operating experience.

Main features include:

4-axis processing capability: provides more processing freedom and multi-angle operation, suitable for complex 3D engraving and stereo processing.

Automatic tool change system (ATC): equipped with advanced automatic tool change system, no manual tool change is required, fast and accurate tool change is achieved, and production efficiency is improved.

Multi-functional drilling head: integrates multiple functions such as drilling and boring, suitable for various processing needs, from simple hole processing to complex positioning hole operations.

High precision and stability: adopts high-quality guide rails and stable machine tool structure to ensure high-precision processing quality and long-term stable operation.

Choose our 4axis ATC cnc machine with Drilling Head to make your processing more efficient and precise, and achieve a wider range of applications and greater production potential. Contact us now for more details and customization options!

Product Parameters

| Product name | 4axis ATC cnc machine with Drilling Head |

| Working area | 1500*mm*3000mm*300mm |

| Spindle power | 9KW HITECO Spindle Head + HITECO Twin Double Aggregate Head + HSD 5+4 Drill Block + 4 Axis Rotary Axis |

| Controller | Syntec 60E Control System |

| Motor&driver | Yaskawa 1000W Servo Motor And Driver*4 |

| Transmission | Precision Taiwan JINGTE Helical gear rack +Three sets Japan SHIMPO reducer1:10 |

| Rail guide | XY axis by J&T 1.5M helical gear rack transmission, Z axis by Taiwan TBI ball screw |

| Table | Vacuum and T-slot Table |

| Machining Accuracy | ±0.1mm |

| Repositioning Resolution | ±0.01mm |

| Rotary Axis | 200mm Diameter, 1500mm length |

Product Details

Spindle ( HITECO Double Head Aggregate Head )

Control system (New Generation 60E control system)

Drive Motor (Yaskawa 1000W Servo Motors )

A Axis Rotary ( 200mm x 1500mm)

Dust Collection System ( ISO 30 8 Tool Magazine)

Countertop Structure ( Vacuum Table )

Vacuum Pump ( 2.2kw Vacuum Pump )

Oiling System ( Automatic Oiling System )

Guard Rail ( Taiwan HIWIN )

Reducer ( Japan Shinpo Reducer )

Spindle Head ( 9KWK HITECO Spindle Head )

Drill Block ( HSD5 +4 Drill Block )

Product Advantages

Application of 4axis ATC cnc machine with Drilling Head

CNC Routers such as the 4axis ATC Cnc Machine with Drilling Head can be used in many different applications such as:

1. Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors, and windows.

2. Wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

3. Plate processing: insulation part, plastic chemical components, PCB, inner body of the car, bowling tracks, stairs, anti-bate board, epoxy resin, ABS, PP, PE, and other carbon mixed compounds.

4. Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic, and soft metals such as copper, aluminum plate engraving, and milling process.

FAQ

Linear Tool Changer & Carousel Tool Changer

The linear tool magazine can be placed under the gantry or behind the machine. The linear tool change usually could be support 4-10 pcs tool holder, and the additional space is limited. The carousel tool magazine can be installed on the side or top of the gantry, or as an independent part outside the machine. A variety of tools for different purposes can be clamped, such as 8, 12, 16, 20 tools, etc., and different processing procedures can be completed through automatic tool change controlled by the CNC system.

The carousel tool changer machining center is more suitable for door panel processing. If you need to use this model for cabinet drilling, slotting and cutting, due to the weight of the gantry, plus a series of accessories such as the spindle and tool magazine, it will affect For the operating speed of the machine, the door panel requires precision. The demand for speed is not as large as the cabinet body. However, the cabinet body processing requires both accuracy and speed. The carousel tool changer can be used to process the cabinet body, but it is not suitable for processing the cabinet body. The linear tool changer machining center is a bit more suitable than the carousel tool change, and it can fully meet the precision and speed required by the cabinet and door panel processing. Moreover, this model of the straight row tool change machining center is more suitable for substituting machining, cabinets, Door panels, embossments, hollows, and lattices can guarantee the processing volume within the production capacity.

Compared with the linear tool changer, the carousel tool change machining center has a higher cost, but the machining accuracy and stability of the carousel tool change machining center will be guaranteed, and the long-term use effect will not be affected.

According to your budget, equipment requirements and processing needs, you can choose the right style. If you don't know how to choose, UTECH will help you.