- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

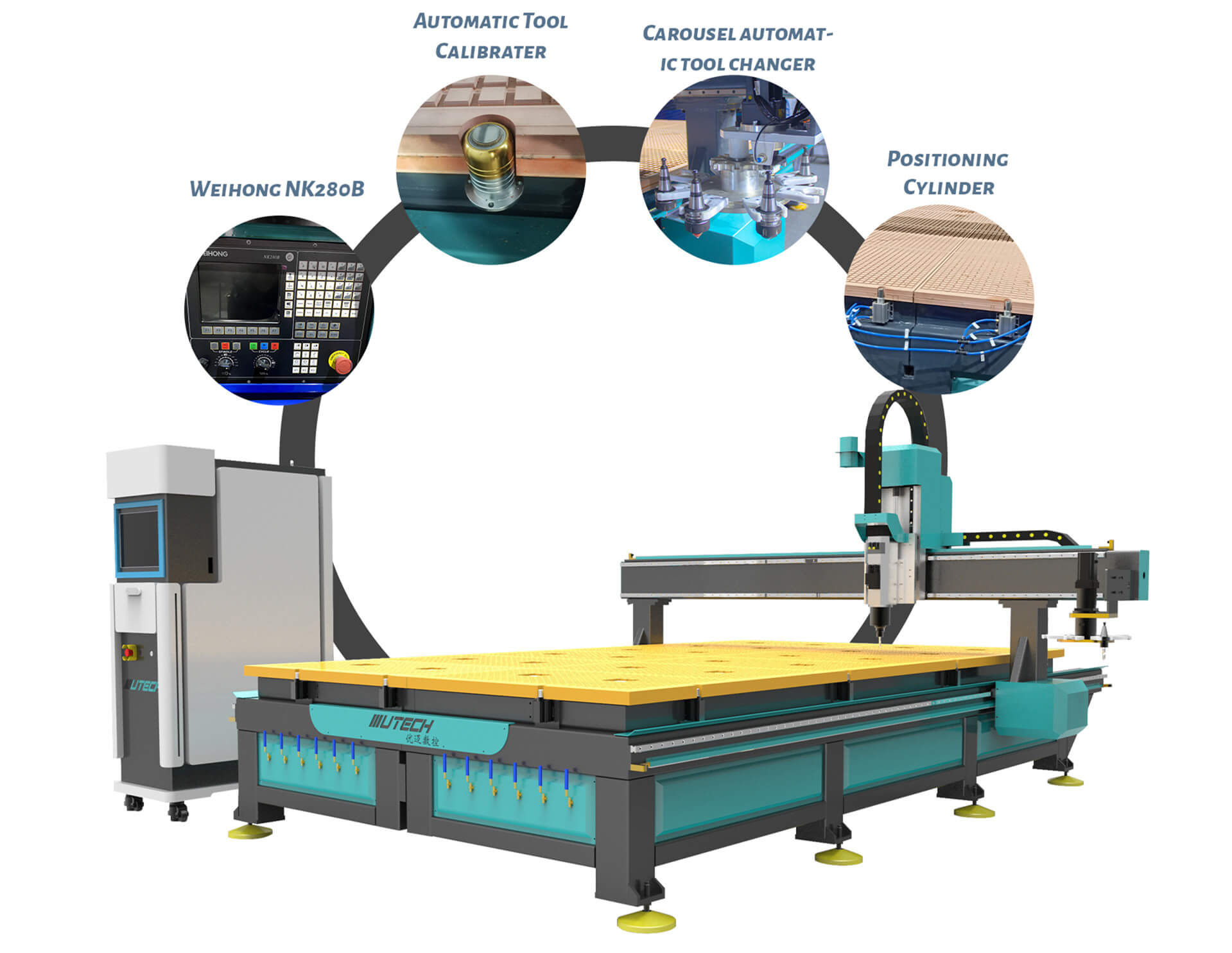

SESAME 2240 ATC CNC Router

The split structure meets the needs of the size to enter the container.

✬Double-layer vacuum adsorption table

✭Splicing bed---Two 1100*4000mm lathe bed.

❆Carousel automatic tool changer

❊Industrial computer control+Wireless hand wheel

♕YASKAWA 850w servo motor&driver

☯1.5M helical rack gear transmission, Japan SHIMPO reducer structure 1:10

♆14 pcs Positioning cylinder

| Working Area: | |

|---|---|

| Table Structure: | |

| Driving System: | |

| Spindle Motor: | |

| Collet: | |

| Availability: | |

SESAME S2 2240 ATC CNC router

UTECH

Atc Cnc Wood Router for Wooden Furniture Door Making

The split structure meets the needs of the size to enter the container.

✬Double-layer vacuum adsorption table

✭Splicing bed---Two 1100*4000mm lathe bed.

❆Carousel automatic tool changer

❊Industrial computer control+Wireless hand wheel

♕YASKAWA 850w servo motor&driver

☯1.5M helical rack gear transmission, Japan SHIMPO reducer structure 1:10

♆14 pcs Positioning cylinder

1/ Weihong NK280B Controller

NK280B is widely used in CNC engraving and milling machines/engraving machines. It is one of the representatives of Weihong's highly reliable and cost-effective motion control system; supports 4-axis linkage; supports Yaskawa M-II and Weizhi servo bus absolute value; serial Communication; I/O can be expanded with an 8-inch LCD display, embedded platform, and customers can carry out secondary development of the process.

2/Carousel automatic tool changer

According to the different needs of different customers, there’re different tool magazine capacities that can be chosen, 4, 8, 10, 12, 16, or more, when changing the tool, the machine head moves to the tool magazine, selects the required tool, and returns to continue carving. Realize quick tool change, improve work efficiency. The tool changer can be placed next to the spindle or on the side of the gantry. This carousel tool change method has the feature of faster tool change speed, so the production efficiency is higher. In addition, this tool change method make the machine run more stably, which can ensure higher machining accuracy and higher processing quality.

3/9kw HQD ATC Air Cooled Spindle (HSD is optional)

High precision 9kw air cooling ATC spindle motor, after twice dynamic balance precision testing, can ensure the machining accuracy. Is equipped with an ISO30 tool holder and ER32 collect, programmable speeds of up to 24,000 RPM.

4/Positioning Cylinder

For the standard 1325, the positioning cylinders are usually distributed in 2 on the X-axis and 3 on the Y-axis. These pneumatic devices form an L-shaped right angle. Function: Position the plate to be processed, reduce the time of manual positioning of the plate, and improve the efficiency of plate feeding. After installing the positioning cylinder, it is possible to ensure that each sheet is placed in the same position, without repeating the definition of the workpiece origin to ensure the positioning accuracy, which is simple to operate and saves time. The main point is safety performance. The positioning of the cylinder is also controlled by the control system's program. It has a cross-border protection device. When the positioning shaft of the cylinder extends, the machine automatically stops working to prevent the spindle tool from cutting the cylinder or the cylinder shaft from damaging the tool. , Can avoid unnecessary losses in a limited way.

5/SHIMPO Reducer

UTECH equipment is equipped with standard reducer structure---patented step reducer/Japan SHIMPO reducer 1:5/1:10. Compared with the reduction gear and the structure inside the gear box, the belt of the timing belt has a certain tension and is easy to loosen. It is often necessary to change the belt. There is also a gear box for the machine to decelerate. When the machine needs to decelerate and stop, the gear box has no effect. Obviously, and due to the use of timing belts, great inertia is easy to slip and overtravel.

The reducer has the characteristics of low backlash, low noise, high strength, and accurate deceleration effect.

6/Vacuum Table&T-slot Table

Unique multipurpose bakelite plate vacuum and aluminum clamping bed, with 4-8 adsorption zone, could be independent control to achieve adsorb and clamp.

The vacuum table is with multi zones, which allows the operator to switch from full sheet processing to smaller part processing. Every vacuum zone is controlled by separated valves on the front of the machine, and whole vacuum zones are with one general valve to control.

7/Transmission

UTECH ATC CNC Series Rack adopts high-precision 1.5M helical gear rack, which is complementary with the professional motor and professional deceleration device, which runs smoothly, high speed, high precision and low noise. Adapt PMI 25 Linear guide+Flange slider+precision 1.5M helical rack transmission structures can ensure that Running stably and reliably, working life is long, the machine can keep working for a long time.

8/Automatic Tool Calibrator

The equipment with the tool calibrater can automatically set the offset value of the tool to the workpiece coordinate system after the tool setting, so that the workpiece coordinate system can be automatically established. In this way, the setting of the workpiece coordinate value can be easily realized. It can be said that the use of the tool setting instrument not only saves time, but also improves efficiency.

9/Wireless hand wheel

It is an operating tool when the engraving and milling machine is manually moved. It is used in the correction of the origin of the CNC machine tool and the division of the signal, and the operation is convenient.

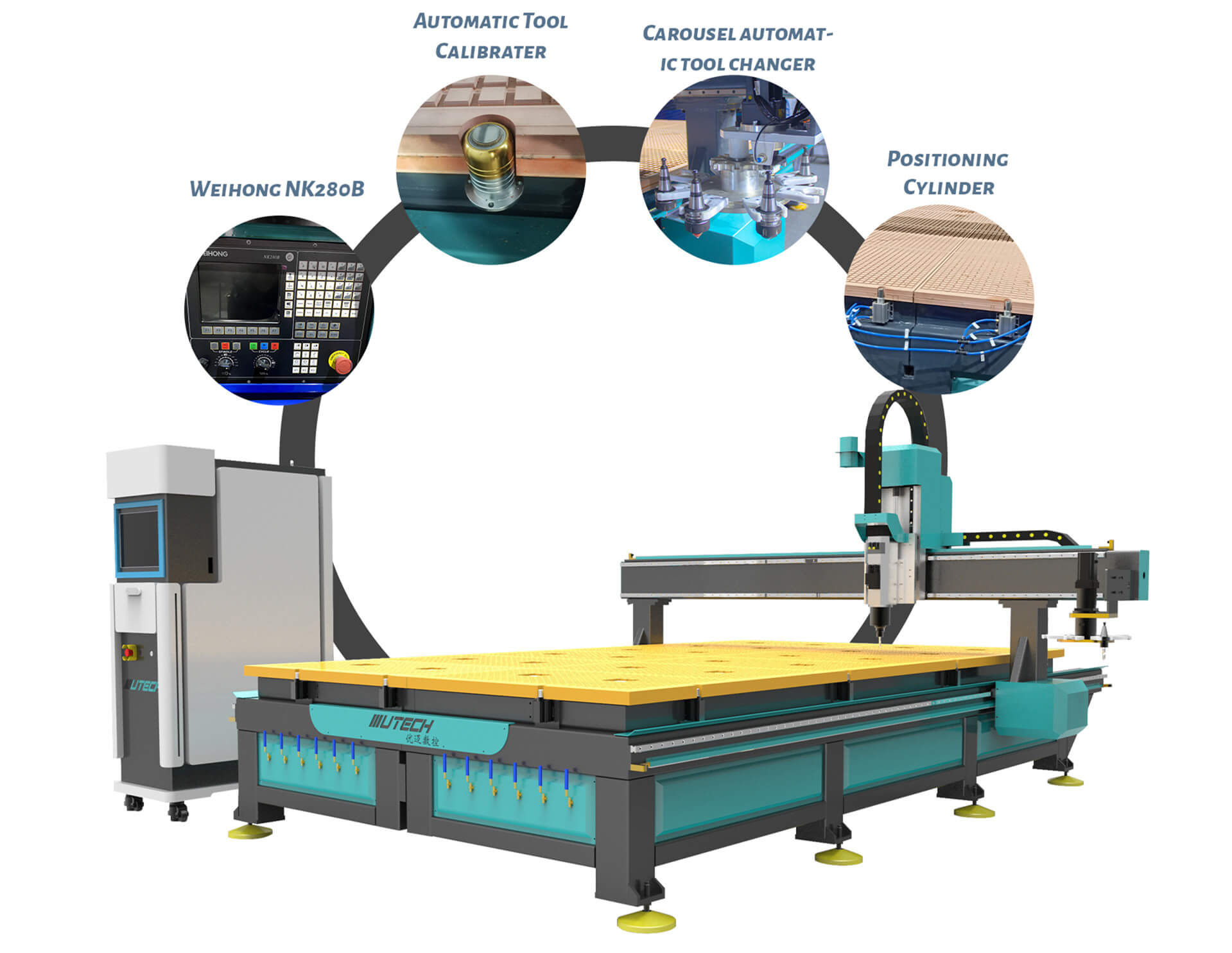

Atc Cnc Wood Router for Wooden Furniture Door Making

The split structure meets the needs of the size to enter the container.

✬Double-layer vacuum adsorption table

✭Splicing bed---Two 1100*4000mm lathe bed.

❆Carousel automatic tool changer

❊Industrial computer control+Wireless hand wheel

♕YASKAWA 850w servo motor&driver

☯1.5M helical rack gear transmission, Japan SHIMPO reducer structure 1:10

♆14 pcs Positioning cylinder

1/ Weihong NK280B Controller

NK280B is widely used in CNC engraving and milling machines/engraving machines. It is one of the representatives of Weihong's highly reliable and cost-effective motion control system; supports 4-axis linkage; supports Yaskawa M-II and Weizhi servo bus absolute value; serial Communication; I/O can be expanded with an 8-inch LCD display, embedded platform, and customers can carry out secondary development of the process.

2/Carousel automatic tool changer

According to the different needs of different customers, there’re different tool magazine capacities that can be chosen, 4, 8, 10, 12, 16, or more, when changing the tool, the machine head moves to the tool magazine, selects the required tool, and returns to continue carving. Realize quick tool change, improve work efficiency. The tool changer can be placed next to the spindle or on the side of the gantry. This carousel tool change method has the feature of faster tool change speed, so the production efficiency is higher. In addition, this tool change method make the machine run more stably, which can ensure higher machining accuracy and higher processing quality.

3/9kw HQD ATC Air Cooled Spindle (HSD is optional)

High precision 9kw air cooling ATC spindle motor, after twice dynamic balance precision testing, can ensure the machining accuracy. Is equipped with an ISO30 tool holder and ER32 collect, programmable speeds of up to 24,000 RPM.

4/Positioning Cylinder

For the standard 1325, the positioning cylinders are usually distributed in 2 on the X-axis and 3 on the Y-axis. These pneumatic devices form an L-shaped right angle. Function: Position the plate to be processed, reduce the time of manual positioning of the plate, and improve the efficiency of plate feeding. After installing the positioning cylinder, it is possible to ensure that each sheet is placed in the same position, without repeating the definition of the workpiece origin to ensure the positioning accuracy, which is simple to operate and saves time. The main point is safety performance. The positioning of the cylinder is also controlled by the control system's program. It has a cross-border protection device. When the positioning shaft of the cylinder extends, the machine automatically stops working to prevent the spindle tool from cutting the cylinder or the cylinder shaft from damaging the tool. , Can avoid unnecessary losses in a limited way.

5/SHIMPO Reducer

UTECH equipment is equipped with standard reducer structure---patented step reducer/Japan SHIMPO reducer 1:5/1:10. Compared with the reduction gear and the structure inside the gear box, the belt of the timing belt has a certain tension and is easy to loosen. It is often necessary to change the belt. There is also a gear box for the machine to decelerate. When the machine needs to decelerate and stop, the gear box has no effect. Obviously, and due to the use of timing belts, great inertia is easy to slip and overtravel.

The reducer has the characteristics of low backlash, low noise, high strength, and accurate deceleration effect.

6/Vacuum Table&T-slot Table

Unique multipurpose bakelite plate vacuum and aluminum clamping bed, with 4-8 adsorption zone, could be independent control to achieve adsorb and clamp.

The vacuum table is with multi zones, which allows the operator to switch from full sheet processing to smaller part processing. Every vacuum zone is controlled by separated valves on the front of the machine, and whole vacuum zones are with one general valve to control.

7/Transmission

UTECH ATC CNC Series Rack adopts high-precision 1.5M helical gear rack, which is complementary with the professional motor and professional deceleration device, which runs smoothly, high speed, high precision and low noise. Adapt PMI 25 Linear guide+Flange slider+precision 1.5M helical rack transmission structures can ensure that Running stably and reliably, working life is long, the machine can keep working for a long time.

8/Automatic Tool Calibrator

The equipment with the tool calibrater can automatically set the offset value of the tool to the workpiece coordinate system after the tool setting, so that the workpiece coordinate system can be automatically established. In this way, the setting of the workpiece coordinate value can be easily realized. It can be said that the use of the tool setting instrument not only saves time, but also improves efficiency.

9/Wireless hand wheel

It is an operating tool when the engraving and milling machine is manually moved. It is used in the correction of the origin of the CNC machine tool and the division of the signal, and the operation is convenient.

Patent separable structure

As we all know, the usual width of a container is 2350mm. For a CNC with 2200x4000mm working size, the successful transportation stems from UTECH's patented split design.

Patent separable structure

As we all know, the usual width of a container is 2350mm. For a CNC with 2200x4000mm working size, the successful transportation stems from UTECH's patented split design.

Machine name | SESAME 2240 ATC CNC router |

Working table | Vaccum table and pump |

Workable size | 2200x4000x200mm |

Spindle motor | HQD 9kw air cooling spindle |

Control system | Weihong NK280B Controller |

X Y Z traveling Positioning accuracy | ±0.01 |

Max Working Speed | 24000mm/min |

Working Voltage | AC380V/50/60HZ |

Command language | G Code |

Operating system | YASKAWA servo motor |

X,Y,Z Guide Rail | Taiwan 25 Square Rail |

Computer Interface | USB |

Flash memory | 128M(U Disk) |

Collet | ISO30 |

Software | Type3/Wentai/Artcam |

Machine name | SESAME 2240 ATC CNC router |

Working table | Vaccum table and pump |

Workable size | 2200x4000x200mm |

Spindle motor | HQD 9kw air cooling spindle |

Control system | Weihong NK280B Controller |

X Y Z traveling Positioning accuracy | ±0.01 |

Max Working Speed | 24000mm/min |

Working Voltage | AC380V/50/60HZ |

Command language | G Code |

Operating system | YASKAWA servo motor |

X,Y,Z Guide Rail | Taiwan 25 Square Rail |

Computer Interface | USB |

Flash memory | 128M(U Disk) |

Collet | ISO30 |

Software | Type3/Wentai/Artcam |

CNC Routers such as the SESAME 2240 Carousel ATC CNC Router can be used in many different applications such as:

1. Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors, and windows.

2. Wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

3. Plate processing: insulation part, plastic chemical components, PCB, inner body of the car, bowling tracks, stairs, anti-bate board, epoxy resin, ABS, PP, PE, and other carbon mixed compounds.

4. Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic, and soft metals such as copper, aluminum plate engraving, and milling process.

CNC Routers such as the SESAME 2240 Carousel ATC CNC Router can be used in many different applications such as:

1. Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors, and windows.

2. Wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

3. Plate processing: insulation part, plastic chemical components, PCB, inner body of the car, bowling tracks, stairs, anti-bate board, epoxy resin, ABS, PP, PE, and other carbon mixed compounds.

4. Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic, and soft metals such as copper, aluminum plate engraving, and milling process.

Packing:

1/ If the machine is delivered via LCL, then would be packed with wrapping film, EPE foam, and a standard export plywood box.

2/ If machine delivery via FCL, then don't need a wood box, would be packed with wrapping film and EPE foam.

Shipping:

We support machine delivery via express, air transportation, land transportation, and sea transportation.

1/ Such as some small machine, Mini CNC Router or Small CO2 Laser Machine and Fiber Laser Marking Machine, usually delivered via

express and air transportation.

2/ If you wanna us to help you deliver to a domestic warehouse or Russia, Kazakhstan, etc, usually delivered via land transportation.

3/ Large machines or some countries where shipping is more convenient, usually suggest choosing sea transportation.

You can choose any way you'd prefer, we also will give you some proper suggestions.

Packing:

1/ If the machine is delivered via LCL, then would be packed with wrapping film, EPE foam, and a standard export plywood box.

2/ If machine delivery via FCL, then don't need a wood box, would be packed with wrapping film and EPE foam.

Shipping:

We support machine delivery via express, air transportation, land transportation, and sea transportation.

1/ Such as some small machine, Mini CNC Router or Small CO2 Laser Machine and Fiber Laser Marking Machine, usually delivered via

express and air transportation.

2/ If you wanna us to help you deliver to a domestic warehouse or Russia, Kazakhstan, etc, usually delivered via land transportation.

3/ Large machines or some countries where shipping is more convenient, usually suggest choosing sea transportation.

You can choose any way you'd prefer, we also will give you some proper suggestions.