- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Working Table Size: | |

|---|---|

| Spindle Motor Power: | |

| Control system: | |

| Drive motor: | |

| Availability: | |

Plasma

UTECH

UT-1325P

CNC Plasma Cutting Machine / Plasma Cutter / Plasma Cut CNC

Description:

UTECH Industrial Electric Plasma CNC Machine For Metal Materials is a professional high-quality metal cutting machine. It can cut almost any metal very well, from steel, stainless steel, aluminum, copper, titanium, etc., and is suitable for different industries such as sheet metal, kitchenware, parts, and decoration industries. Our machine uses CNC working method and can read DXF/PLT format files. After uploading the file to the machine, the machine will cut quickly and accurately according to your pattern. Digital ways of working provide maximum flexibility and help our customers meet changing requirements. With UTECH Industrial Electric Plasma CNC Machine For Metal Materials, metal can be cut quickly and accurately. If you have such needs, please contact us for more information.

Standard Parts:

1) 1300*2500mm working area(1530, 2030, 2040, 2060 could be customized)

2) Beijing STARFIRE control system+Arc Height Controller

3) Huayuan 63A power supply (According to your work)

4) JMC stepper motor&driver

5) Gear rack and square rail guide transmission

6) Sawtooth table

7) Heavy duty machine body with 5mm thick square tube

8) FASTCAM software

9) Instruction of STARFIRE control system and FASTCAM software.

Optional parts:

1) Servo motor&driver(any brnad)

2) Huayuan 63A, 100A, 120A, 160A, 200A; Hypertherm 45A, 65A, 85A, 105A, 125A

3) Water tank/Water table

4) Flat table

5) Fangling control system

Etc.

Advantages of cnc plasma cutter machine:

1. Cutting faster, more accurate control, the cutting surface is more smooth, no glitches, no black; cutting holes in high

quality.

2. Stability and reliability for light path system and control system.

3. Humanizing design, convenient operation.

4. High-performance price ratio, low operating cost >High cutting efficiency, and quality, no noisy. Small heat influence area,cutting seam smooth and no deformation, post-treatment is not needed.

5. The machine adopts Beijing START plasma control system, standard high sensitivity arc voltage device

6. High precision stepper motor and driver, ensure the efficiency and accuracy, increasing the stability and reliability greatly.

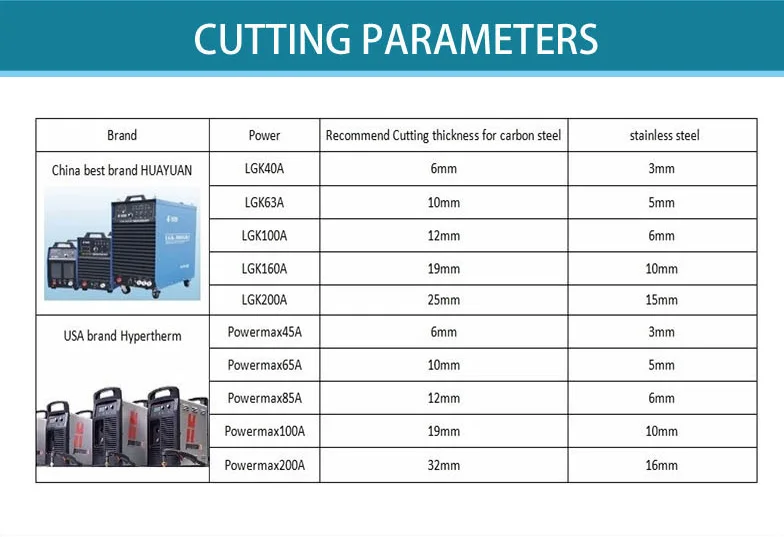

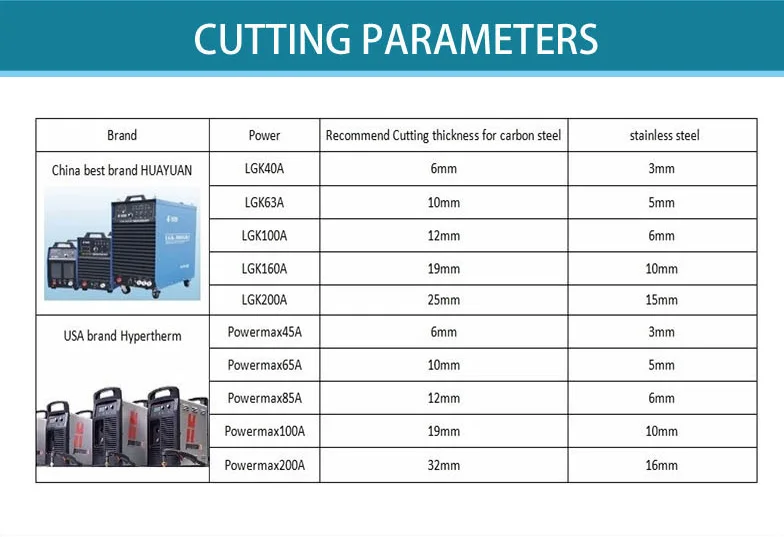

Some differences between Huayuan and Hypertherm power supply:

PS, if you're not sure which kind of plasma power is suitable for you, you can share the following information for me, I'll suggest you choose proper type.

1/ Which kind of metal materials you wanna cut?

2/ How about the cutting thickness?

Details:

Name | Specification |

Working Area(X*Y) | 1300×2500mm |

Machine Structure | Welded |

X Y Guide Rail | Taiwan HIWIN Square Rail |

X Y Transmission | Imported Rack gears |

Drive Mode | Stepper Motor (Optional Servo ) |

Control System | START |

Max thickness | 0.3-22mm |

Plasma Generator | 100A Huanyuan plasma power |

Cutting Speed | 0-8000mm/min |

Working Voltage | 3-Phase 380V/2-phrase 220V |

G.W. | 1200KGS |

Application:

♦ Application Materials: Stainless steel, mild steel, brass, copper, aluminum alloy, sheet metal, spring steel, gold, silver, etc

♦ Application Industry: Sheet metal, kitchenware, components, decorations industry

Package Details:

The machine will be packed with wrapping film, EPE foam, and wooden case(composite material box/plywood case).

SESAME CNC Router's machine legs and machine bed can be separated freely, when machine shipping, we'll dismantle the machine legs, they can help you save more shipping fee.

1. Our Wooden Case is after fumigation treatment. Needn`t timber inspection, saving shipping time.

2. All the spare parts of the machine were covered by some soft materials, mainly using Pearl Wool. Avoiding all damages that could happen in the delivery process. Then we`ll cover plastic wrap out it tightly, make sure intact of the covered soft materials, also avoiding Waterproof and rustproof.

3. The outmost is Wooden Case With Fixed Formwork.

4. The bottom of the wooden case has a firm iron jack, convenient for handling and transport.

Company service:

Shandong U-May Cnc Technology Co., Ltd. is a professional manufacturer of CNC machinery. Our goal is to provide high-quality products at competitive prices and provide complete after-sales service to provide one-stop service.

1. Whole machine with one year warranty, within one year, if there has parts broken, you can send back to us, then we'll send a new one to you.

2. Free training course at our plant or on line.

3. After the warranty period, we'll provide the consumable parts at an agency price when you need replacement.

4. 24 hours on line service each day, free technical support.

5. Before machine delivery, we'll install all parts and test machine for you. We'll take machine's working video and machine photos for you for checking, if confirmed there're no problem, then we'll delivery machine. And if dont dismantle the gantry (if working area more than 1325, then need dismantle machine gantry for putting it into container), after machine arrived, you just need connect plasma power supply, software etc, it's more easily for you. If you're worried, we can take a teaching video for you at that time. By the way, during the production of machine, we also can share the process with you.

6. As for training, firstly we'll take more teaching video for you, and we also can remote control, most important, if you need, we can provide our technicians for on-site training and on-site teaching. And if you wanna, welcome to visit us, you can operate and learn your machine by yourself.

7. After machine shipped, I'll prepare some documents, like B/L, Packing List, Commerical Invoice, Commerical Contract, CE certificate for helping you pick up your machine.

CNC Plasma Cutting Machine / Plasma Cutter / Plasma Cut CNC

Description:

UTECH Industrial Electric Plasma CNC Machine For Metal Materials is a professional high-quality metal cutting machine. It can cut almost any metal very well, from steel, stainless steel, aluminum, copper, titanium, etc., and is suitable for different industries such as sheet metal, kitchenware, parts, and decoration industries. Our machine uses CNC working method and can read DXF/PLT format files. After uploading the file to the machine, the machine will cut quickly and accurately according to your pattern. Digital ways of working provide maximum flexibility and help our customers meet changing requirements. With UTECH Industrial Electric Plasma CNC Machine For Metal Materials, metal can be cut quickly and accurately. If you have such needs, please contact us for more information.

Standard Parts:

1) 1300*2500mm working area(1530, 2030, 2040, 2060 could be customized)

2) Beijing STARFIRE control system+Arc Height Controller

3) Huayuan 63A power supply (According to your work)

4) JMC stepper motor&driver

5) Gear rack and square rail guide transmission

6) Sawtooth table

7) Heavy duty machine body with 5mm thick square tube

8) FASTCAM software

9) Instruction of STARFIRE control system and FASTCAM software.

Optional parts:

1) Servo motor&driver(any brnad)

2) Huayuan 63A, 100A, 120A, 160A, 200A; Hypertherm 45A, 65A, 85A, 105A, 125A

3) Water tank/Water table

4) Flat table

5) Fangling control system

Etc.

Advantages of cnc plasma cutter machine:

1. Cutting faster, more accurate control, the cutting surface is more smooth, no glitches, no black; cutting holes in high

quality.

2. Stability and reliability for light path system and control system.

3. Humanizing design, convenient operation.

4. High-performance price ratio, low operating cost >High cutting efficiency, and quality, no noisy. Small heat influence area,cutting seam smooth and no deformation, post-treatment is not needed.

5. The machine adopts Beijing START plasma control system, standard high sensitivity arc voltage device

6. High precision stepper motor and driver, ensure the efficiency and accuracy, increasing the stability and reliability greatly.

Some differences between Huayuan and Hypertherm power supply:

PS, if you're not sure which kind of plasma power is suitable for you, you can share the following information for me, I'll suggest you choose proper type.

1/ Which kind of metal materials you wanna cut?

2/ How about the cutting thickness?

Details:

Name | Specification |

Working Area(X*Y) | 1300×2500mm |

Machine Structure | Welded |

X Y Guide Rail | Taiwan HIWIN Square Rail |

X Y Transmission | Imported Rack gears |

Drive Mode | Stepper Motor (Optional Servo ) |

Control System | START |

Max thickness | 0.3-22mm |

Plasma Generator | 100A Huanyuan plasma power |

Cutting Speed | 0-8000mm/min |

Working Voltage | 3-Phase 380V/2-phrase 220V |

G.W. | 1200KGS |

Application:

♦ Application Materials: Stainless steel, mild steel, brass, copper, aluminum alloy, sheet metal, spring steel, gold, silver, etc

♦ Application Industry: Sheet metal, kitchenware, components, decorations industry

Package Details:

The machine will be packed with wrapping film, EPE foam, and wooden case(composite material box/plywood case).

SESAME CNC Router's machine legs and machine bed can be separated freely, when machine shipping, we'll dismantle the machine legs, they can help you save more shipping fee.

1. Our Wooden Case is after fumigation treatment. Needn`t timber inspection, saving shipping time.

2. All the spare parts of the machine were covered by some soft materials, mainly using Pearl Wool. Avoiding all damages that could happen in the delivery process. Then we`ll cover plastic wrap out it tightly, make sure intact of the covered soft materials, also avoiding Waterproof and rustproof.

3. The outmost is Wooden Case With Fixed Formwork.

4. The bottom of the wooden case has a firm iron jack, convenient for handling and transport.

Company service:

Shandong U-May Cnc Technology Co., Ltd. is a professional manufacturer of CNC machinery. Our goal is to provide high-quality products at competitive prices and provide complete after-sales service to provide one-stop service.

1. Whole machine with one year warranty, within one year, if there has parts broken, you can send back to us, then we'll send a new one to you.

2. Free training course at our plant or on line.

3. After the warranty period, we'll provide the consumable parts at an agency price when you need replacement.

4. 24 hours on line service each day, free technical support.

5. Before machine delivery, we'll install all parts and test machine for you. We'll take machine's working video and machine photos for you for checking, if confirmed there're no problem, then we'll delivery machine. And if dont dismantle the gantry (if working area more than 1325, then need dismantle machine gantry for putting it into container), after machine arrived, you just need connect plasma power supply, software etc, it's more easily for you. If you're worried, we can take a teaching video for you at that time. By the way, during the production of machine, we also can share the process with you.

6. As for training, firstly we'll take more teaching video for you, and we also can remote control, most important, if you need, we can provide our technicians for on-site training and on-site teaching. And if you wanna, welcome to visit us, you can operate and learn your machine by yourself.

7. After machine shipped, I'll prepare some documents, like B/L, Packing List, Commerical Invoice, Commerical Contract, CE certificate for helping you pick up your machine.