- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Spindle Motor Power: | |

|---|---|

| Control system: | |

| Plasma power: | |

| Cutting thickness: | |

| Worktable: | |

| Availability: | |

Plasma

UTECH

UT-1325P

UTECH Sesame Series Plasma CNC Router For Metal And Nonmetal

Working area: 1200*1200mm, 1300*2500mm, 1500*3000mm, 2000*4000mm etc.

Plasma power: Huayuan 63A, 100A, 120A, 160A, 200A

Hypertherm 45A, 65A, 85A, 105A, 125A

Machine Description:

CNC plasma cutter is a computer-controlled machine with a cutting table, a plasma generator, and other CNC kits. We also call it CNC plasma table, CNC plasma cutting table, CNC plasma cutting machine, etc. It is the most popular metal cutting machine in this world. Because it can cut almost any metal well in quality, from steel, stainless steel, aluminum, copper, titanium, etc. CNC plasma cutter also has the advantages of fast cutting speed, smooth cut surface, little heat distortion & deformation.

1) Support FASTCAM nesting software such as the standard G code path generated file can also be also can change software to read AUTOCAD softwares produce DXF form documents. U disk exchange control system processing files, easy to operate.

4) High cutting speed, high precision, and low cost.

Features of plasma cutting machine:

♦ working area: 1300*2500mm

♦ Heavy duty thicken machine body

♦ 200A Hypertherm plasma power

♦ Stepper motor and Leadshine Driver

♦ Start Controller system from Beijing

♦ Automatic Arc Pressure adjustable

♦ HIWIN Linear Guide Rail

♦ Helical Rack and Pinion

♦ Fast Cam software

♦ warranty : 1 year

CNC plasma cutting machine advantages:

| 1. Plasma power | Hypertherm 200A power Famous brand all of the world, low price, Cutting thickness 0.3-52mm |

| 2. Controller system | Beijing Start control system, configured 7-inch high-resolution true color LCD display. can be dynamically cut graphics running track. |

| 3. Motor | 450B stepper motors With high quality & stronger power, ensure machine work very well. |

| 4. Driver | Leadshine 860H Drivers It can run with smaller noise, lower heating, smoother movement and have better performances at higher speed.Save human strength and save time. |

| 5. Automatic Arc Pressure adjustable | Beijing Start Adjust the torch height during cutting. Perforated height self-positioning |

| 6. software | Fast Cam nesting software for machine. Using it, and finally export G code, then can be recognized by machine |

Standard Configurations:

1) 1300*2500mm working area(1530, 2030, 2040, 2060 could be customized)

2) Beijing STARFIRE control system+Arc Height Controller

3) Huayuan 63A power supply (According to your work)

4) JMC stepper motor&driver

5) Gear rack and square rail guide transmission

6) Sawtooth table

7) Heavy duty machine body with 5mm thick square tube

8) FASTCAM software

9) Instruction of STARFIRE control system and FASTCAM software.

Optional parts:

1) Servo motor&driver(any brnad)

2) Huayuan 63A, 100A, 120A, 160A, 200A; Hypertherm 45A, 65A, 85A, 105A, 125A

3) Water tank/Water table

4) Flat table

5) Fangling control system

Etc.

CNC plasma cutting machine applications:

It is widely used in the process of cutting metal plates in the machinery manufacturing industry, engineering industry, and metal fabrication and can cut mild steel, stainless steel, aluminum, copper and many kinds of non-ferrous metal.

Advertising industry:

Advertising signs, logo making, decorative products, production of advertising and avariety of metal materials.

Metal industry:

For steel, Carbon Steel, Stainless steel, alloy steel, spring steel, copper plate, aluminium plate,gold, silver, Titanium and other metal plate and tube.

CNC plasma cutting machine's description:

| Model | UT-1325P CNC Plasma cutting machine (Other models are optional) |

| Working size | 1300x2500mm (4x8ft) (Other working sizes are optional) |

| Three axes repeat positioning accuracy | ±0.05mm |

| Process precision | ±0.35mm |

| Transmission system | X, Y: Taiwan Hiwin high-precision, zero clearance increased linear guide+ rack Z: the arc voltage control |

| Max. cutting speed | 15000mm/min |

| Working voltage | AC220/50HZ |

| Control system | Starfire plasma cutting system Standard high sensitivity arc voltage device |

| Software support | FASTCAM,AutoCAD,etc |

| Instruction format | G code |

| Drive system | Stepper motor |

| Plasma power supply | Huayuan 63A/120A/160A/200A. Optional, USA Hypertherm, 45A/65A/85A/105A/125A |

PS, Working area, Plasma power, Power supply's brand, Machine color, all could be customized for you.

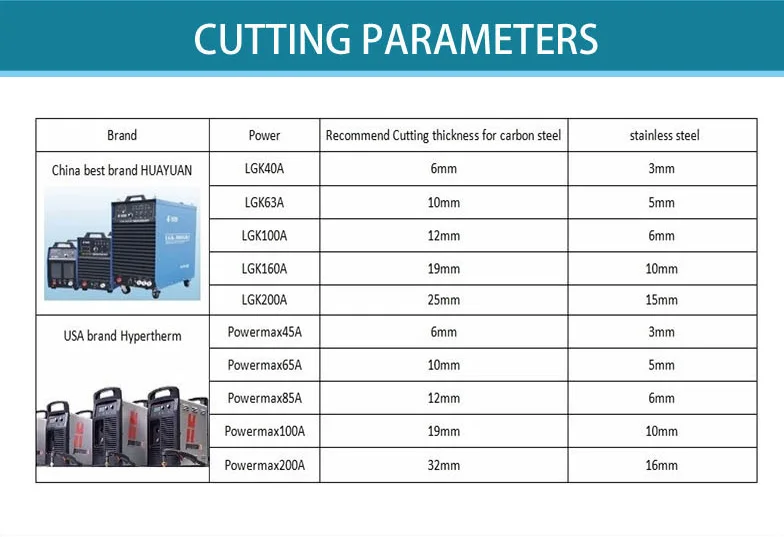

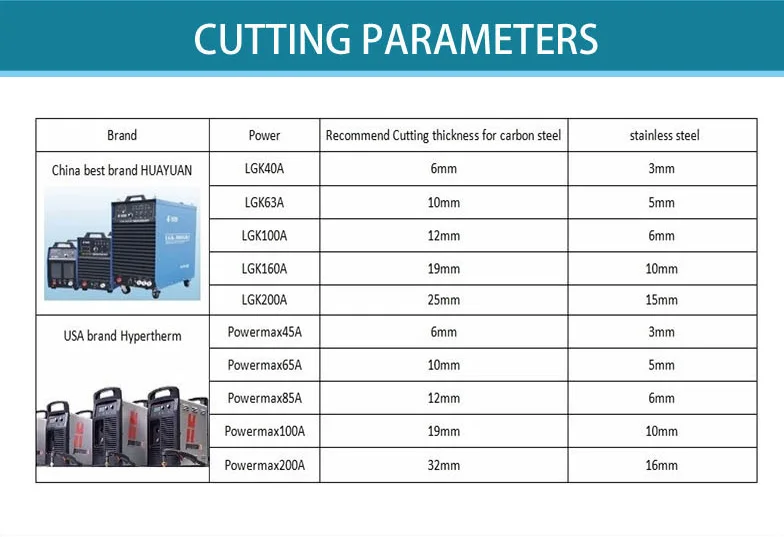

Some differences between Huayuan and Hypertherm power supply:

PS, if you're not sure which kind of plasma power is suitable for you, you can share the following information for me, I'll suggest you choose proper type.

1/ Which kind of metal materials you wanna cut?

2/ How about the cutting thickness?

UTECH Sesame Series Plasma CNC Router For Metal And Nonmetal

Working area: 1200*1200mm, 1300*2500mm, 1500*3000mm, 2000*4000mm etc.

Plasma power: Huayuan 63A, 100A, 120A, 160A, 200A

Hypertherm 45A, 65A, 85A, 105A, 125A

Machine Description:

CNC plasma cutter is a computer-controlled machine with a cutting table, a plasma generator, and other CNC kits. We also call it CNC plasma table, CNC plasma cutting table, CNC plasma cutting machine, etc. It is the most popular metal cutting machine in this world. Because it can cut almost any metal well in quality, from steel, stainless steel, aluminum, copper, titanium, etc. CNC plasma cutter also has the advantages of fast cutting speed, smooth cut surface, little heat distortion & deformation.

1) Support FASTCAM nesting software such as the standard G code path generated file can also be also can change software to read AUTOCAD softwares produce DXF form documents. U disk exchange control system processing files, easy to operate.

4) High cutting speed, high precision, and low cost.

Features of plasma cutting machine:

♦ working area: 1300*2500mm

♦ Heavy duty thicken machine body

♦ 200A Hypertherm plasma power

♦ Stepper motor and Leadshine Driver

♦ Start Controller system from Beijing

♦ Automatic Arc Pressure adjustable

♦ HIWIN Linear Guide Rail

♦ Helical Rack and Pinion

♦ Fast Cam software

♦ warranty : 1 year

CNC plasma cutting machine advantages:

| 1. Plasma power | Hypertherm 200A power Famous brand all of the world, low price, Cutting thickness 0.3-52mm |

| 2. Controller system | Beijing Start control system, configured 7-inch high-resolution true color LCD display. can be dynamically cut graphics running track. |

| 3. Motor | 450B stepper motors With high quality & stronger power, ensure machine work very well. |

| 4. Driver | Leadshine 860H Drivers It can run with smaller noise, lower heating, smoother movement and have better performances at higher speed.Save human strength and save time. |

| 5. Automatic Arc Pressure adjustable | Beijing Start Adjust the torch height during cutting. Perforated height self-positioning |

| 6. software | Fast Cam nesting software for machine. Using it, and finally export G code, then can be recognized by machine |

Standard Configurations:

1) 1300*2500mm working area(1530, 2030, 2040, 2060 could be customized)

2) Beijing STARFIRE control system+Arc Height Controller

3) Huayuan 63A power supply (According to your work)

4) JMC stepper motor&driver

5) Gear rack and square rail guide transmission

6) Sawtooth table

7) Heavy duty machine body with 5mm thick square tube

8) FASTCAM software

9) Instruction of STARFIRE control system and FASTCAM software.

Optional parts:

1) Servo motor&driver(any brnad)

2) Huayuan 63A, 100A, 120A, 160A, 200A; Hypertherm 45A, 65A, 85A, 105A, 125A

3) Water tank/Water table

4) Flat table

5) Fangling control system

Etc.

CNC plasma cutting machine applications:

It is widely used in the process of cutting metal plates in the machinery manufacturing industry, engineering industry, and metal fabrication and can cut mild steel, stainless steel, aluminum, copper and many kinds of non-ferrous metal.

Advertising industry:

Advertising signs, logo making, decorative products, production of advertising and avariety of metal materials.

Metal industry:

For steel, Carbon Steel, Stainless steel, alloy steel, spring steel, copper plate, aluminium plate,gold, silver, Titanium and other metal plate and tube.

CNC plasma cutting machine's description:

| Model | UT-1325P CNC Plasma cutting machine (Other models are optional) |

| Working size | 1300x2500mm (4x8ft) (Other working sizes are optional) |

| Three axes repeat positioning accuracy | ±0.05mm |

| Process precision | ±0.35mm |

| Transmission system | X, Y: Taiwan Hiwin high-precision, zero clearance increased linear guide+ rack Z: the arc voltage control |

| Max. cutting speed | 15000mm/min |

| Working voltage | AC220/50HZ |

| Control system | Starfire plasma cutting system Standard high sensitivity arc voltage device |

| Software support | FASTCAM,AutoCAD,etc |

| Instruction format | G code |

| Drive system | Stepper motor |

| Plasma power supply | Huayuan 63A/120A/160A/200A. Optional, USA Hypertherm, 45A/65A/85A/105A/125A |

PS, Working area, Plasma power, Power supply's brand, Machine color, all could be customized for you.

Some differences between Huayuan and Hypertherm power supply:

PS, if you're not sure which kind of plasma power is suitable for you, you can share the following information for me, I'll suggest you choose proper type.

1/ Which kind of metal materials you wanna cut?

2/ How about the cutting thickness?

Company Information:

"///UTECH" is the new logo brand after the transformation of "Shandong U-May CNC Technology Co., Ltd.". "/// "aims to record the important strategic transformation of the company from ordinary business innovation to high-quality operation in the three years after its establishment; "U" is "U-May"'s homophonic characters; "TECH" means the CNC technology. At the same time, when the company was founded three years, the establishment of the Ministry of Foreign Trade, so "///UTECH" became the company's new logo, and the company's development philosophy "Smarter Solution, Better Tomorrow."

Our Service:

1. Whole machine with one year warranty, within one year, if there has parts broken, you can send back to us, then we'll send a new one to you.

2. Free training course at our plant or on line.

3. After the warranty period, we'll provide the consumable parts at an agency price when you need replacement.

4. 24 hours on line service each day, free technical support.

5. Before machine delivery, we'll install all parts and test machine for you. We'll take machine's working video and machine photos for you for checking, if confirmed there're no problem, then we'll delivery machine. And if dont dismantle the gantry (if working area more than 1325, then need dismantle machine gantry for putting it into container), after machine arrived, you just need connect plasma power supply, software etc, it's more easily for you. If you're worried, we can take a teaching video for you at that time. By the way, during the production of machine, we also can share the process with you.

6. As for training, firstly we'll take more teaching video for you, and we also can remote control, most important, if you need, we can provide our technicians for on-site training and on-site teaching. And if you wanna, welcome to visit us, you can operate and learn your machine by yourself.

7. After machine shipped, I'll prepare some documents, like B/L, Packing List, Commerical Invoice, Commerical Contract, CE certificate for helping you pick up your machine.

Company Information:

"///UTECH" is the new logo brand after the transformation of "Shandong U-May CNC Technology Co., Ltd.". "/// "aims to record the important strategic transformation of the company from ordinary business innovation to high-quality operation in the three years after its establishment; "U" is "U-May"'s homophonic characters; "TECH" means the CNC technology. At the same time, when the company was founded three years, the establishment of the Ministry of Foreign Trade, so "///UTECH" became the company's new logo, and the company's development philosophy "Smarter Solution, Better Tomorrow."

Our Service:

1. Whole machine with one year warranty, within one year, if there has parts broken, you can send back to us, then we'll send a new one to you.

2. Free training course at our plant or on line.

3. After the warranty period, we'll provide the consumable parts at an agency price when you need replacement.

4. 24 hours on line service each day, free technical support.

5. Before machine delivery, we'll install all parts and test machine for you. We'll take machine's working video and machine photos for you for checking, if confirmed there're no problem, then we'll delivery machine. And if dont dismantle the gantry (if working area more than 1325, then need dismantle machine gantry for putting it into container), after machine arrived, you just need connect plasma power supply, software etc, it's more easily for you. If you're worried, we can take a teaching video for you at that time. By the way, during the production of machine, we also can share the process with you.

6. As for training, firstly we'll take more teaching video for you, and we also can remote control, most important, if you need, we can provide our technicians for on-site training and on-site teaching. And if you wanna, welcome to visit us, you can operate and learn your machine by yourself.

7. After machine shipped, I'll prepare some documents, like B/L, Packing List, Commerical Invoice, Commerical Contract, CE certificate for helping you pick up your machine.