- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

UT-1325

UTECH

UT-1325

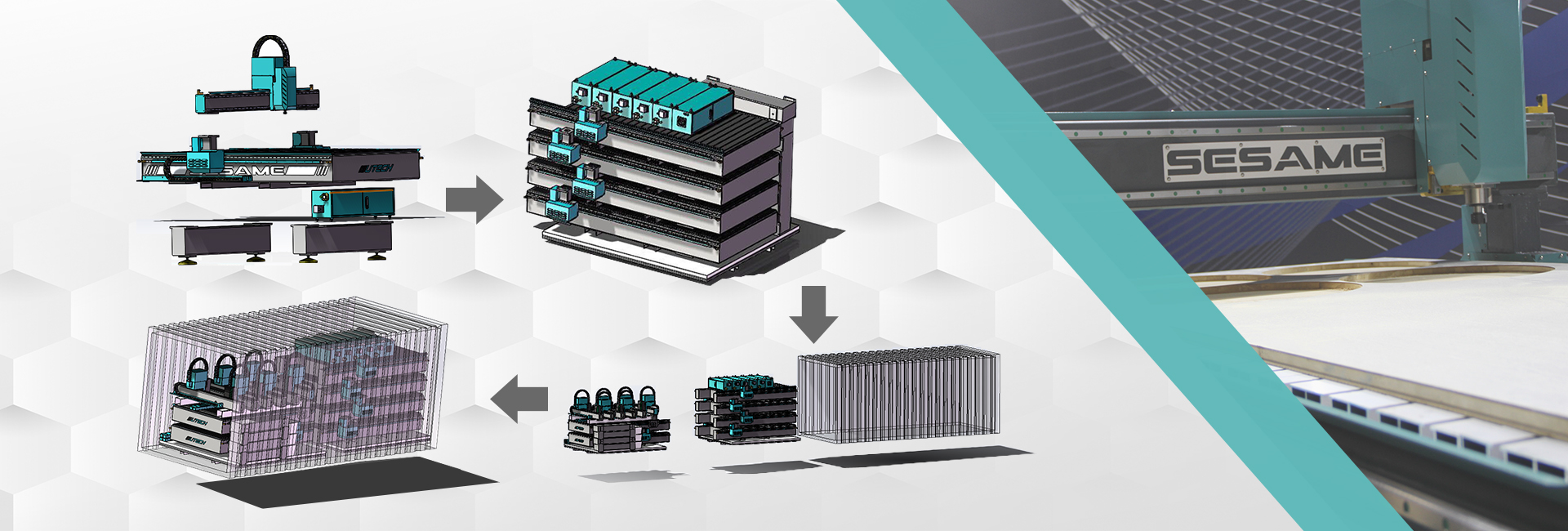

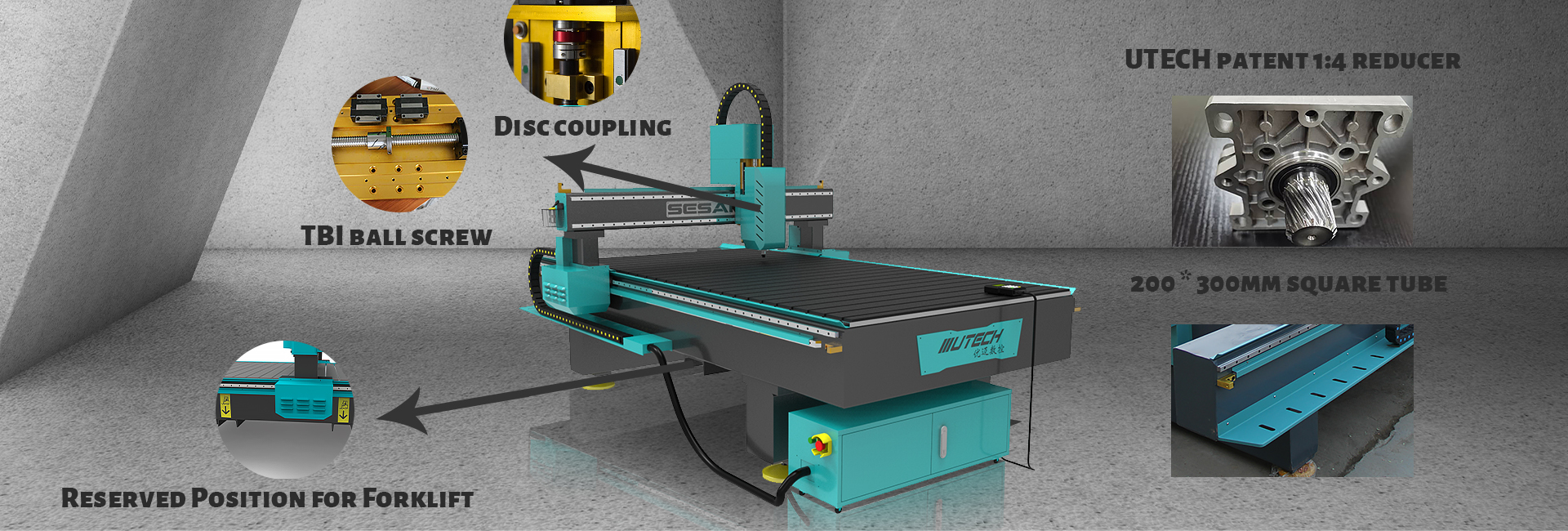

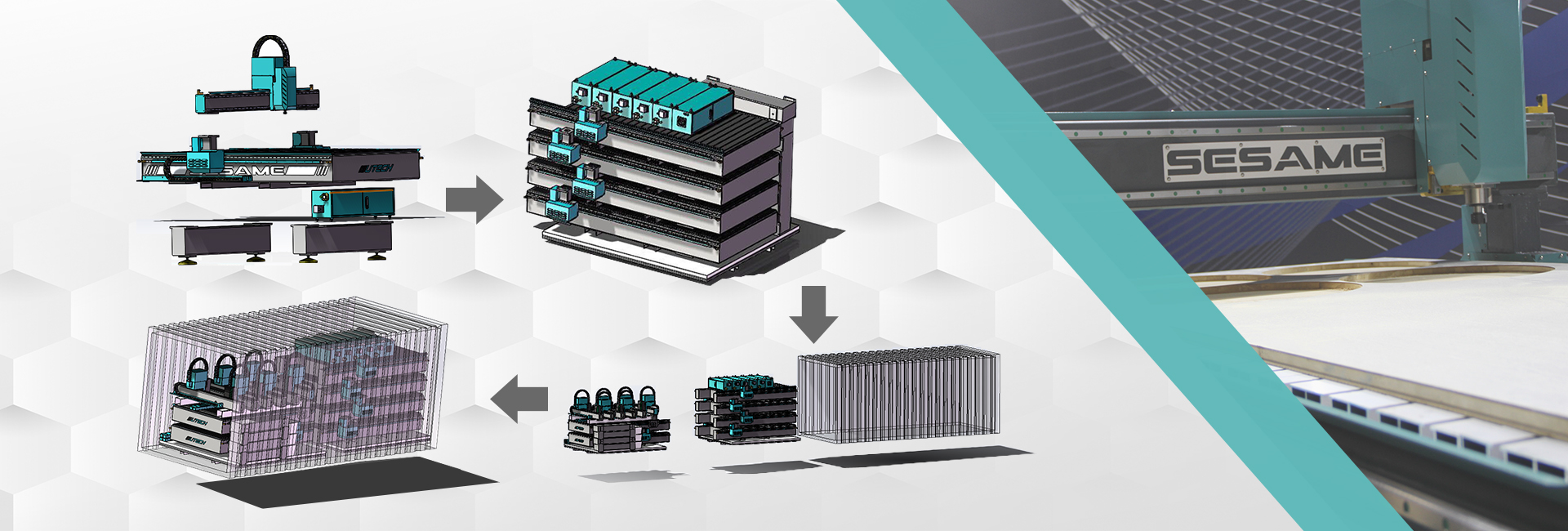

UTECH have two hot sale type cnc router, one is SOFIA Series, the other is SESAME Series. The following type is SESAME-S2 type, standard type with 4.5kw spindle, stepper motor&driver+UTECH patent type reducer, could improve the process speed. CCD, Oscillating knife, Auto tool changer, 4th rotary is optional.

Suitable for advertising and woodworking industry, acrylic, wood, plastic, foam, MDF, plywood, aluminum etc. If you dont know how to choose, weclome to ask us, we'll provide proper solution with you.

Description:

A CNC router is a computer-controlled cutting machine that is commonly used in woodworking, metalworking, and other fabrication applications. It operates based on instructions programmed into its computer system, allowing for precise and automated cutting, shaping, and carving of materials.

The basic functions of a CNC router include:

Cutting: A CNC router can cut a wide range of materials such as wood, plastic, foam, and even metals. It can accurately follow programmed paths to cut out intricate shapes, patterns, and profiles.

Carving and Engraving: The router is capable of creating detailed carvings and engravings on different surfaces. It can accurately replicate designs and produce intricate textures and patterns.

Routing and Milling: With a rotating cutting tool, such as a router bit or an end mill, a CNC router can remove material by rotating and moving along multiple axes. This allows for precise routing, shaping, and milling operations on the workpiece.

Drilling: A CNC router can accurately drill holes at specified locations and depths. It can perform single or multiple hole drilling operations, making it useful for tasks that require precise hole placement.

Contouring and Profiling: By following programmed paths, a CNC router can create smooth and consistent contours and profiles on the workpiece. This capability is particularly valuable for producing curved or irregular shapes.

Pocketing and Grooving: The router can create pockets and grooves by removing material from specific areas. This function is commonly used for creating recesses, channels, or joinery features in the workpiece.

Surface Finishing: Many CNC routers have the ability to perform surface finishing operations, such as sanding or polishing. This helps to achieve a smooth and refined final product.

Automation and Repetition: One of the key advantages of CNC routers is their ability to automate tasks and repeat them accurately. Once a design is programmed, the machine can reproduce it consistently, making it suitable for batch production or creating multiple identical parts.

In summary, a CNC router provides versatile and precise capabilities for cutting, carving, shaping, and drilling operations. It offers increased efficiency and accuracy compared to manual machining methods, making it a valuable tool in various industries.

Details:

Details:

| Machine structure: | ||

| Serial number | Structure | Brand |

| 1 | Control System | Nc-studio controller/Mach3 controller |

| 2 | Transmission system | 1.25 modulus precision gear rack and Taiwan TBI ball screw |

| 3 | Driving system | JMC stepper driver+Patent type stepper reducer*3+stepper motor |

| 4 | Spindle motor | 4.5KW air cooling spindle |

| 5 | Inverter | Best inverter |

| 6 | Limit switch | Japan Omron limit switch |

| 7 | Rail guide | Taiwan PMI linear guide+Flange Slider |

| 8 | Driver motor | Leadshine 450B |

| 9 | Machine table | Aluminum alloy T-slot table |

| 10 | Voltage | 220v/380v 50Hz |

| 11 | Case/Cabinet | Portable optimization design small sub-body independent control cabinet |

| 12 | Working area | 1300*2500*180mm |

SESAME Cnc Router's standard parts:

Standard Specifications:

7/ Working size 1212, 1530, 2030, 2040 etc.

Applications:

| Furniture industry | Ambry door, wood door, solid wood, annatto furniture, archaize furniture all kinds of compound plank cutting and engraving | |

| Panel processing industry | Insulation parts, plastic chemical parts, PCB, anti-double panel, epoxy resin, ABS, PP, PE and other carbon mixtures | |

| Arts & Crafts | Artificial stone, PVC, wood, bamboo, marble, organic glass, copper aluminum etc | |

| Decoration Industry | The screen, wave plate, bamboo, marble, organic board, double color board and other materials on various fine patterns and the engraving of words | |

SESAME Cnc Router's advantages:

The High quality SESAME series CNC Router machine comes with 4.5kw water or 3.2kw air cooled high frequency spindle. This precision spindle requires no maintenance, uses industry standard ER collects. Fully programmable speeds from 6000 to 24000RPM, and comes complete with pneumatically retractable vacuum hood.

1) Higher efficiency than traditional ball screws.

2) Gothic groove shape, the shaft direction clearance can be adjusted to a minimum and can be easily transferred.

3) The internal circulation method is applicable to many different scenes, and the circulation method is selected according to its own needs.

4) Use rigorous materials, high heat treatment and processing technology to supply durable products.

CNC Tool Sensor allows for easy and accurate "Z" zero position for single and multiple tool changes through the program.

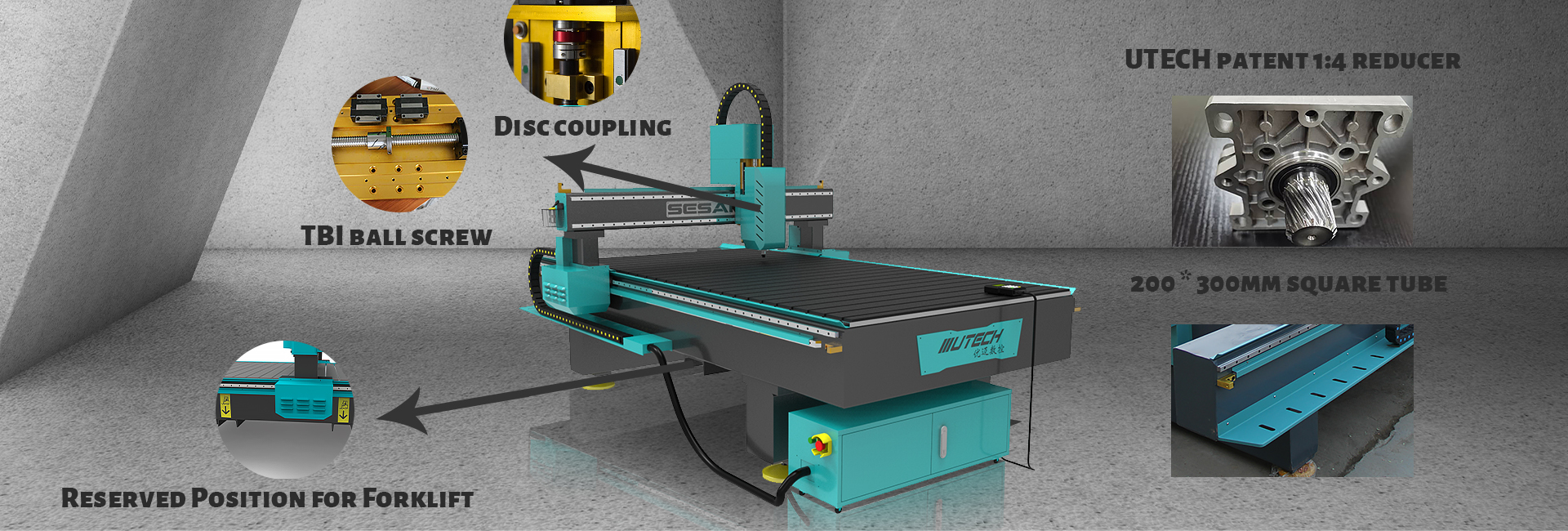

UTECH have two hot sale type cnc router, one is SOFIA Series, the other is SESAME Series. The following type is SESAME-S2 type, standard type with 4.5kw spindle, stepper motor&driver+UTECH patent type reducer, could improve the process speed. CCD, Oscillating knife, Auto tool changer, 4th rotary is optional.

Suitable for advertising and woodworking industry, acrylic, wood, plastic, foam, MDF, plywood, aluminum etc. If you dont know how to choose, weclome to ask us, we'll provide proper solution with you.

Description:

A CNC router is a computer-controlled cutting machine that is commonly used in woodworking, metalworking, and other fabrication applications. It operates based on instructions programmed into its computer system, allowing for precise and automated cutting, shaping, and carving of materials.

The basic functions of a CNC router include:

Cutting: A CNC router can cut a wide range of materials such as wood, plastic, foam, and even metals. It can accurately follow programmed paths to cut out intricate shapes, patterns, and profiles.

Carving and Engraving: The router is capable of creating detailed carvings and engravings on different surfaces. It can accurately replicate designs and produce intricate textures and patterns.

Routing and Milling: With a rotating cutting tool, such as a router bit or an end mill, a CNC router can remove material by rotating and moving along multiple axes. This allows for precise routing, shaping, and milling operations on the workpiece.

Drilling: A CNC router can accurately drill holes at specified locations and depths. It can perform single or multiple hole drilling operations, making it useful for tasks that require precise hole placement.

Contouring and Profiling: By following programmed paths, a CNC router can create smooth and consistent contours and profiles on the workpiece. This capability is particularly valuable for producing curved or irregular shapes.

Pocketing and Grooving: The router can create pockets and grooves by removing material from specific areas. This function is commonly used for creating recesses, channels, or joinery features in the workpiece.

Surface Finishing: Many CNC routers have the ability to perform surface finishing operations, such as sanding or polishing. This helps to achieve a smooth and refined final product.

Automation and Repetition: One of the key advantages of CNC routers is their ability to automate tasks and repeat them accurately. Once a design is programmed, the machine can reproduce it consistently, making it suitable for batch production or creating multiple identical parts.

In summary, a CNC router provides versatile and precise capabilities for cutting, carving, shaping, and drilling operations. It offers increased efficiency and accuracy compared to manual machining methods, making it a valuable tool in various industries.

Details:

Details:

| Machine structure: | ||

| Serial number | Structure | Brand |

| 1 | Control System | Nc-studio controller/Mach3 controller |

| 2 | Transmission system | 1.25 modulus precision gear rack and Taiwan TBI ball screw |

| 3 | Driving system | JMC stepper driver+Patent type stepper reducer*3+stepper motor |

| 4 | Spindle motor | 4.5KW air cooling spindle |

| 5 | Inverter | Best inverter |

| 6 | Limit switch | Japan Omron limit switch |

| 7 | Rail guide | Taiwan PMI linear guide+Flange Slider |

| 8 | Driver motor | Leadshine 450B |

| 9 | Machine table | Aluminum alloy T-slot table |

| 10 | Voltage | 220v/380v 50Hz |

| 11 | Case/Cabinet | Portable optimization design small sub-body independent control cabinet |

| 12 | Working area | 1300*2500*180mm |

SESAME Cnc Router's standard parts:

Standard Specifications:

7/ Working size 1212, 1530, 2030, 2040 etc.

Applications:

| Furniture industry | Ambry door, wood door, solid wood, annatto furniture, archaize furniture all kinds of compound plank cutting and engraving | |

| Panel processing industry | Insulation parts, plastic chemical parts, PCB, anti-double panel, epoxy resin, ABS, PP, PE and other carbon mixtures | |

| Arts & Crafts | Artificial stone, PVC, wood, bamboo, marble, organic glass, copper aluminum etc | |

| Decoration Industry | The screen, wave plate, bamboo, marble, organic board, double color board and other materials on various fine patterns and the engraving of words | |

SESAME Cnc Router's advantages:

The High quality SESAME series CNC Router machine comes with 4.5kw water or 3.2kw air cooled high frequency spindle. This precision spindle requires no maintenance, uses industry standard ER collects. Fully programmable speeds from 6000 to 24000RPM, and comes complete with pneumatically retractable vacuum hood.

1) Higher efficiency than traditional ball screws.

2) Gothic groove shape, the shaft direction clearance can be adjusted to a minimum and can be easily transferred.

3) The internal circulation method is applicable to many different scenes, and the circulation method is selected according to its own needs.

4) Use rigorous materials, high heat treatment and processing technology to supply durable products.

CNC Tool Sensor allows for easy and accurate "Z" zero position for single and multiple tool changes through the program.