- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Machine Function: | |

|---|---|

| Working Area: | |

| Tool Magazine: | |

| Toolholder Quantity: | |

| Repositioning Resolution: | |

| Spindle Power&Speed: | |

| Driver&Motors: | |

| Availability: | |

UT-Zpro

UTECH

Atc Oscillating Knife Cutting Cnc Router Machine with CCD

ZPRO is a multifunctional engraving machine launched by UTECH. The machine is equipped with high-precision spindle + CCD + oscillating knife, and also adds automatic tool change function. One machine realizes different functions including engraving, cutting, automatic edge tracking, oscillating knife, automatic tool change, etc. The spindle motor of ZPRO adopts high-precision water-cooled spindle, which has the characteristics of high precision and high stability. The industrial-grade CCD camera and high-frequency oscillating knife equipped on the other side of the machine have high detection accuracy, fast processing speed, strong anti-interference ability, save material waste, very few product consumables, and safe and stable operation. In addition, ZPRO is highly automated, can automatically adjust the working parameters according to your settings, and automatically change the tool according to different materials or processing requirements, reduce manual intervention, improve production efficiency, and reduce production costs. ZPRO has a wide range of applicability and can be perfectly used in various industries such as advertising industry, furniture industry, plate processing industry, handicraft industry, decoration industry, etc. Choose UTECH multifunctional engraving machine to open a new era of efficient and precise processing.

Product Parameters

| Model | ZPRO |

| Machine Function | Spindle+CCD camera+EOT Oscillating knife cutting head |

| Working Area | 1300*2500mm |

| Tool Magazine | Concealed Linear Tool Magazine |

| Toolholder Quantity | ISO20 toolholder x8 |

| Repositioning Resolution | ±0.01mm |

| XY-axis Transmission | 40 tooth-1.5M/H50 gear rack, 25mm guide rail |

| Z-axis Transmission | TBl-SFU2510 ball screw&disc coupling, 20mm guide rail |

| Spindle Power&Speed | 4KW water-cooled spindle&40000rpm |

| Driver&Motors | LeadShine 750W servo motor and driver |

| Reducer | Japan SHlMPO reducer structure 1:10 |

| Operating System | VC-204C PC version |

| Lubrication System | Auto lubration system for sliders and guide rails |

| Gross Power | 16KW |

| Power Consumption | 16kwh/h |

Atc Oscillating Knife Cutting Cnc Router Machine with CCD

ZPRO is a multifunctional engraving machine launched by UTECH. The machine is equipped with high-precision spindle + CCD + oscillating knife, and also adds automatic tool change function. One machine realizes different functions including engraving, cutting, automatic edge tracking, oscillating knife, automatic tool change, etc. The spindle motor of ZPRO adopts high-precision water-cooled spindle, which has the characteristics of high precision and high stability. The industrial-grade CCD camera and high-frequency oscillating knife equipped on the other side of the machine have high detection accuracy, fast processing speed, strong anti-interference ability, save material waste, very few product consumables, and safe and stable operation. In addition, ZPRO is highly automated, can automatically adjust the working parameters according to your settings, and automatically change the tool according to different materials or processing requirements, reduce manual intervention, improve production efficiency, and reduce production costs. ZPRO has a wide range of applicability and can be perfectly used in various industries such as advertising industry, furniture industry, plate processing industry, handicraft industry, decoration industry, etc. Choose UTECH multifunctional engraving machine to open a new era of efficient and precise processing.

Product Parameters

| Model | ZPRO |

| Machine Function | Spindle+CCD camera+EOT Oscillating knife cutting head |

| Working Area | 1300*2500mm |

| Tool Magazine | Concealed Linear Tool Magazine |

| Toolholder Quantity | ISO20 toolholder x8 |

| Repositioning Resolution | ±0.01mm |

| XY-axis Transmission | 40 tooth-1.5M/H50 gear rack, 25mm guide rail |

| Z-axis Transmission | TBl-SFU2510 ball screw&disc coupling, 20mm guide rail |

| Spindle Power&Speed | 4KW water-cooled spindle&40000rpm |

| Driver&Motors | LeadShine 750W servo motor and driver |

| Reducer | Japan SHlMPO reducer structure 1:10 |

| Operating System | VC-204C PC version |

| Lubrication System | Auto lubration system for sliders and guide rails |

| Gross Power | 16KW |

| Power Consumption | 16kwh/h |

1. High-speed water cooling spindle

The spindle motor adopts RH80DXS-2.5/ISO20-40000r/PM tool-changing spindle, which can not only provide powerful and precise processing capabilities, but also maintain a constant speed during long-term high-speed operation, reducing the risk of performance degradation or damage caused by overheating. It is also equipped with an automatic tool-changing system, which can quickly and accurately change tools, improve production efficiency and flexibly respond to various processing needs.

2.CCD Camera

The other side of the machine is equipped with an industrial-grade HIKVISION CCD camera and a high-power vibration knife. Equipped with a professional 1.5 million pixel industrial camera, it has powerful image recognition capabilities and more accurate cutting.High detection accuracy, fast processing speed, strong anti-interference ability, safe and stable operation.

3.High-power oscillating knife

The 150W high-power oscillate knife can complete the cutting task faster and is more efficient when processing materials with higher hardness. It saves material waste and increases material utilization by more than 10%. It is environmentally friendly, smoke-free and dust-free, and the product consumables are very few.

4.High-precision guide rails and racks

Equipped with high-precision steel belt guide rails, Taiwan-J&T 1.5M high-precision bevel racks, high-precision 1.5M-40 tooth large gears, strong load-bearing capacity, fast speed, smooth operation, high precision, low noise and long life.

5.Working table

The table is made of vacuum adsorption, and the table is made of 25MM thick PVC. The adsorption area is distributed in 4 zones and 8 openings to increase the surface area and improve the adsorption efficiency.

6.Leadshine Driver

The whole machine drive system is equipped with Leadshine L6-750W AC servo motor drive, which can make the machine processing faster and more stable. It adopts a well-known brand drive system with high reliability.

7.Japan SHIMPO 1:10 reducer

The machine adopts Japan SHIMPO 1:10 reducer, which has the advantages of small backlash, low noise, high strength, accurate deceleration effect, etc. The reducer is widely used in industrial fields requiring precision control and high performance due to its high precision, high load capacity, compactness and long-term reliability.

8.Bed structure

The X-axis and column of the engraving machine are made of all-aluminum and precision-machined, which maximizes the advantages of machine processing accuracy and running speed, and has greater stability and longer service life.

9.Control system

The machine is equipped with XDW-VC-204A control system, which supports multiple programming languages and multiple data interfaces, and has high compatibility, and can be seamlessly connected with CNC equipment and software systems. It is equipped with a user-friendly graphical interface (HMI) to reduce the complexity of operation.

1. High-speed water cooling spindle

The spindle motor adopts RH80DXS-2.5/ISO20-40000r/PM tool-changing spindle, which can not only provide powerful and precise processing capabilities, but also maintain a constant speed during long-term high-speed operation, reducing the risk of performance degradation or damage caused by overheating. It is also equipped with an automatic tool-changing system, which can quickly and accurately change tools, improve production efficiency and flexibly respond to various processing needs.

2.CCD Camera

The other side of the machine is equipped with an industrial-grade HIKVISION CCD camera and a high-power vibration knife. Equipped with a professional 1.5 million pixel industrial camera, it has powerful image recognition capabilities and more accurate cutting.High detection accuracy, fast processing speed, strong anti-interference ability, safe and stable operation.

3.High-power oscillating knife

The 150W high-power oscillate knife can complete the cutting task faster and is more efficient when processing materials with higher hardness. It saves material waste and increases material utilization by more than 10%. It is environmentally friendly, smoke-free and dust-free, and the product consumables are very few.

4.High-precision guide rails and racks

Equipped with high-precision steel belt guide rails, Taiwan-J&T 1.5M high-precision bevel racks, high-precision 1.5M-40 tooth large gears, strong load-bearing capacity, fast speed, smooth operation, high precision, low noise and long life.

5.Working table

The table is made of vacuum adsorption, and the table is made of 25MM thick PVC. The adsorption area is distributed in 4 zones and 8 openings to increase the surface area and improve the adsorption efficiency.

6.Leadshine Driver

The whole machine drive system is equipped with Leadshine L6-750W AC servo motor drive, which can make the machine processing faster and more stable. It adopts a well-known brand drive system with high reliability.

7.Japan SHIMPO 1:10 reducer

The machine adopts Japan SHIMPO 1:10 reducer, which has the advantages of small backlash, low noise, high strength, accurate deceleration effect, etc. The reducer is widely used in industrial fields requiring precision control and high performance due to its high precision, high load capacity, compactness and long-term reliability.

8.Bed structure

The X-axis and column of the engraving machine are made of all-aluminum and precision-machined, which maximizes the advantages of machine processing accuracy and running speed, and has greater stability and longer service life.

9.Control system

The machine is equipped with XDW-VC-204A control system, which supports multiple programming languages and multiple data interfaces, and has high compatibility, and can be seamlessly connected with CNC equipment and software systems. It is equipped with a user-friendly graphical interface (HMI) to reduce the complexity of operation.

Application

UTECH Atc Oscillating Knife Cutting Cnc Router Machine with CCD is suitable for engraving and milling of various advertising boards, acrylic, insulation boards, compact boards, wood, soft metals, aluminum-plastic boards, plastics, and carbon fiber composite materials. It is widely used in advertising decoration, soft metal and engineering plastic stool board processing.

Application

UTECH Atc Oscillating Knife Cutting Cnc Router Machine with CCD is suitable for engraving and milling of various advertising boards, acrylic, insulation boards, compact boards, wood, soft metals, aluminum-plastic boards, plastics, and carbon fiber composite materials. It is widely used in advertising decoration, soft metal and engineering plastic stool board processing.

Company Information

Shandong U-May CNC Technology Co., Ltd. (UTECH) was founded in Jinan, China in 2014. It has always adhered to the business philosophy of "DO NOTHING OR DO THE BEST" and has been committed to providing high-quality CNC equipment solutions to customers around the world. The company's main products cover various CNC equipment such as CNC machine tools, laser engraving machines, plasma cutting machines, fiber laser cutting machines, laser marking machines, etc., which are widely used in advertising, woodworking, industrial manufacturing, process processing, electronic technology and other fields to meet the personalized needs of customers in different industries. UTECH always adheres to the concept of "customer first" and provides timely maintenance, repair and technical support throughout the purchase process and after-sales service of customers to ensure that customers enjoy professional, efficient and caring service experience throughout the equipment use cycle. With efficient and precise technology, stable and reliable equipment quality and perfect service, UTECH's products are exported to North America, the Middle East, Western Europe, Southeast Asia, Africa, South America and other regions, and a stable dealer agency system has been established in many regions. In the future, UTECH will continue to drive innovation with technology, win trust with service, and work with global customers to create a bright future of intelligent manufacturing!

Company Information

Shandong U-May CNC Technology Co., Ltd. (UTECH) was founded in Jinan, China in 2014. It has always adhered to the business philosophy of "DO NOTHING OR DO THE BEST" and has been committed to providing high-quality CNC equipment solutions to customers around the world. The company's main products cover various CNC equipment such as CNC machine tools, laser engraving machines, plasma cutting machines, fiber laser cutting machines, laser marking machines, etc., which are widely used in advertising, woodworking, industrial manufacturing, process processing, electronic technology and other fields to meet the personalized needs of customers in different industries. UTECH always adheres to the concept of "customer first" and provides timely maintenance, repair and technical support throughout the purchase process and after-sales service of customers to ensure that customers enjoy professional, efficient and caring service experience throughout the equipment use cycle. With efficient and precise technology, stable and reliable equipment quality and perfect service, UTECH's products are exported to North America, the Middle East, Western Europe, Southeast Asia, Africa, South America and other regions, and a stable dealer agency system has been established in many regions. In the future, UTECH will continue to drive innovation with technology, win trust with service, and work with global customers to create a bright future of intelligent manufacturing!

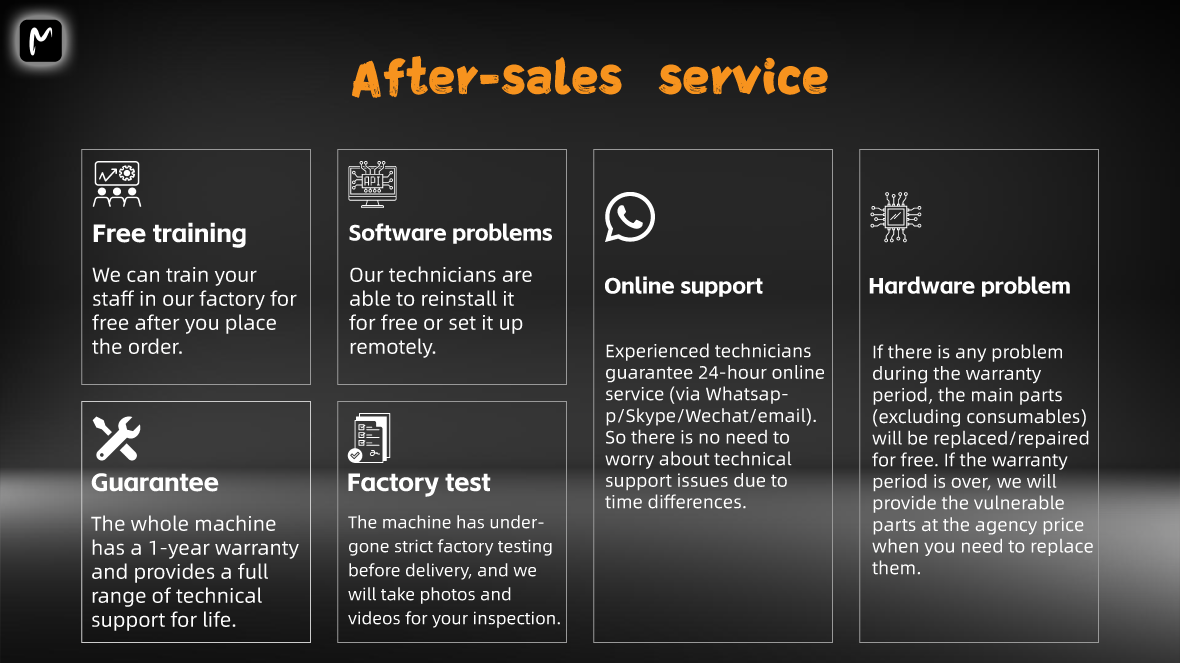

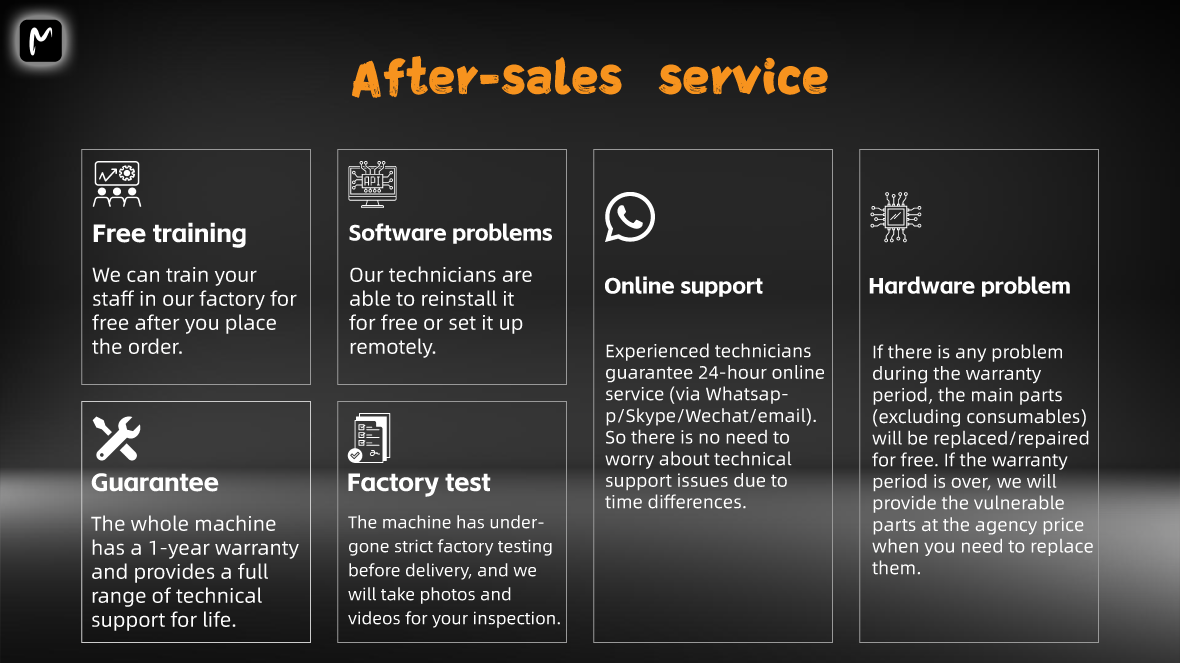

Our Service

Packing&Shipping

Our Service

Packing&Shipping