- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Spindle Motor: | |

|---|---|

| Driving System: | |

| Table Structure: | |

| Control system: | |

| Availability: | |

Sesame

UTECH

UT-1325

4x8ft Cnc Router 1325 Wood Carving Machine for Wooden 3d wood cnc router with rotary

S2 cnc router machine

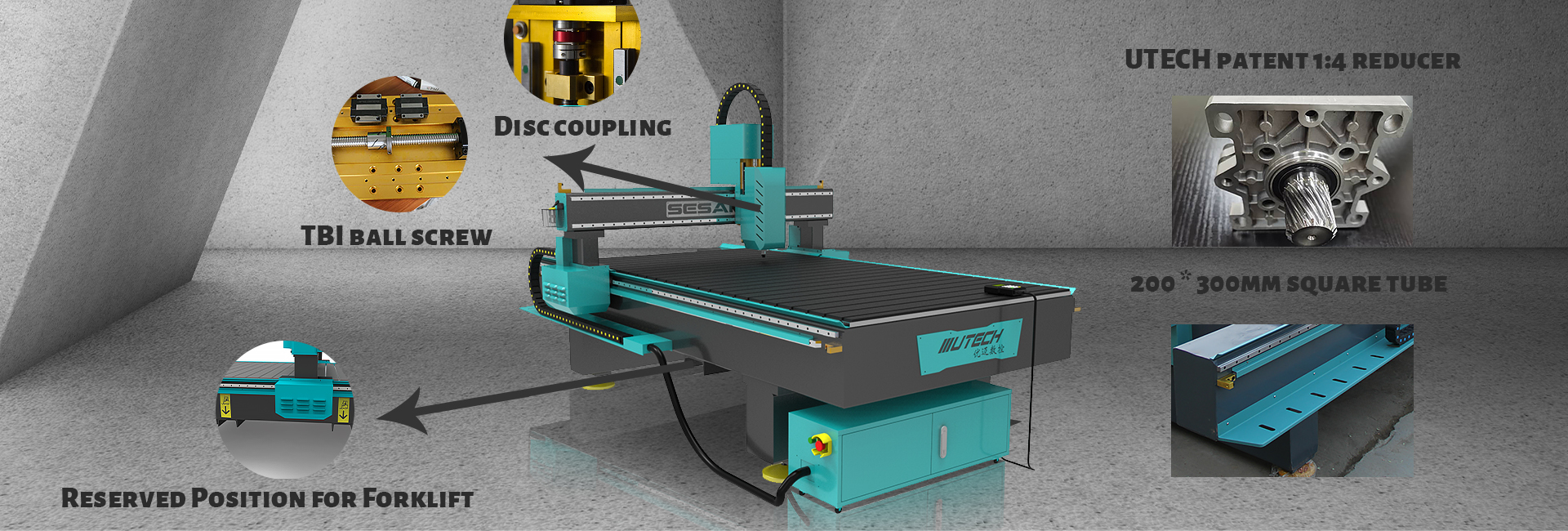

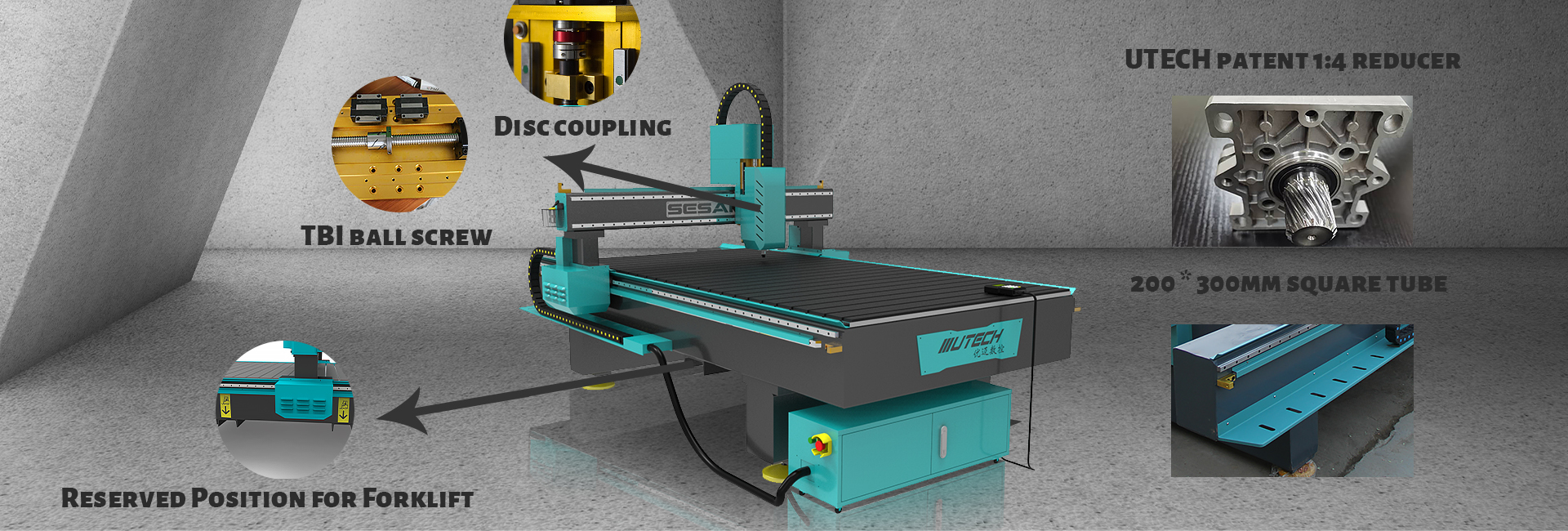

1.UTECH have two hot sale type cnc router, one is SOFIA Series, the other is SESAME Series. The following type is SESAME-S2 type, standard type with 4.5kw spindle, stepper motor&driver+UTECH patent type reducer, could improve the process speed. CCD, Oscillating knife, Auto tool changer, 4th rotary is optional.

UTECH have professional design team and technical person, according to you need, we can make a design drawing for you at first, after you confirmed, we'll start our order.

The following machine's information will help you know more about SESAME.

2.Why choose S2 cnc router machine?

1. 4.5kw water or 4.5kw air cooled high frequency spindle. Fully programmable speeds from 6000 to 24000RPM.

2. Machine bed with 200 * 300mm square tube welded together, more stabilty.

3. Bed welding process increases the reserved forklift.

4. Dust cover for the guide rail and the helical rack and gear.

5. Transmission column, we adopt high - precision machining process, ensure the accuracy of accessories.

6. Double insurance emergency stop switch.

7. Choose heavy duty linear guide rail with high assembly flange sliding block.

8. The machine main body and the machine legs are freely separable.

Description | Parameter |

X, Y, Z Working Area | 1300x2500x180mm |

Table Surface | Aluminum T-slot or vacuum working table |

Structure | Square pipe welding bed structure+150*200mm gantry |

X, Y Structure | XY axis by helical rack transmission |

Z Structure | Taiwan TBI Ball screw and Taiwan PMI Linear guide |

X, Y Resolution | <0.01mm |

Spindle Power | 4.5KW HQD air cooling spindle/Utech 4.5kw water cooling spindle |

Spindle Speed | 0-24000RPM |

Drive Motors | Stepper motor and drive(Servo is optional) |

Inverter | 7kw Inverter |

Control System | Nc-studio or DSP A11 handle controller with USB port |

Lubrication | Manual Lubrication system |

Tool sensor | Manual tool sensor calibration |

Option A | dust collector with 2 pockets (according to your needs) |

Option B | Vacuum table and 5.5kw vacuum pump (according to your needs) |

Option C | Servo motor&driver+Japan SHIMPO reducer |

| Option D | Oil mist cooling system |

| Option E | Rotary axis |

| Option F | CCD camera |

| Option G | Oscillating knife |

| Option H | Auto tool changer |

Control box | Independent Control box |

Limit switch | Japan OMRON limit switch for X, Y, Z axis |

Command Language | G Code |

Computer Interface | USB |

Software Compatibility | ARTCAM software, (Option: JD Paint, Ucancam, Type3 Software) |

Running Environment Temperature | 0 - 45 Centigrade |

Relative Humidity | 30% - 75% |

* Sign Industry: Acrylic sign making, Wood Sign making, ABS board sign making.

* Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

* The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

* Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti-Bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

* Decorate industry: Acrylic, PVC,MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

UTECH has a professional design and technical team to meet all your needs, and the equipment supports customization.

Before confirming the production order, we will provide the rendering picture and 360-degree panoramic video, so that customers can fully understand the style and structure of the machine, so as to ensure that the actual machine meets the requirements of customers, so as to avoid the discrepancy between the real object and customers' imagination caused by various communication deviations.

UTECH technical support is designed to help you make the most of the machine. A variety of technical files and installation videos will be placed in the U disk and shipped with the machine. Our technical experts can provide online remote support and training, and contact UTECH technical support experts in real-time for remote diagnosis. Door-to-door service is also available.

4x8ft Cnc Router 1325 Wood Carving Machine for Wooden 3d wood cnc router with rotary

S2 cnc router machine

1.UTECH have two hot sale type cnc router, one is SOFIA Series, the other is SESAME Series. The following type is SESAME-S2 type, standard type with 4.5kw spindle, stepper motor&driver+UTECH patent type reducer, could improve the process speed. CCD, Oscillating knife, Auto tool changer, 4th rotary is optional.

UTECH have professional design team and technical person, according to you need, we can make a design drawing for you at first, after you confirmed, we'll start our order.

The following machine's information will help you know more about SESAME.

2.Why choose S2 cnc router machine?

1. 4.5kw water or 4.5kw air cooled high frequency spindle. Fully programmable speeds from 6000 to 24000RPM.

2. Machine bed with 200 * 300mm square tube welded together, more stabilty.

3. Bed welding process increases the reserved forklift.

4. Dust cover for the guide rail and the helical rack and gear.

5. Transmission column, we adopt high - precision machining process, ensure the accuracy of accessories.

6. Double insurance emergency stop switch.

7. Choose heavy duty linear guide rail with high assembly flange sliding block.

8. The machine main body and the machine legs are freely separable.

Description | Parameter |

X, Y, Z Working Area | 1300x2500x180mm |

Table Surface | Aluminum T-slot or vacuum working table |

Structure | Square pipe welding bed structure+150*200mm gantry |

X, Y Structure | XY axis by helical rack transmission |

Z Structure | Taiwan TBI Ball screw and Taiwan PMI Linear guide |

X, Y Resolution | <0.01mm |

Spindle Power | 4.5KW HQD air cooling spindle/Utech 4.5kw water cooling spindle |

Spindle Speed | 0-24000RPM |

Drive Motors | Stepper motor and drive(Servo is optional) |

Inverter | 7kw Inverter |

Control System | Nc-studio or DSP A11 handle controller with USB port |

Lubrication | Manual Lubrication system |

Tool sensor | Manual tool sensor calibration |

Option A | dust collector with 2 pockets (according to your needs) |

Option B | Vacuum table and 5.5kw vacuum pump (according to your needs) |

Option C | Servo motor&driver+Japan SHIMPO reducer |

| Option D | Oil mist cooling system |

| Option E | Rotary axis |

| Option F | CCD camera |

| Option G | Oscillating knife |

| Option H | Auto tool changer |

Control box | Independent Control box |

Limit switch | Japan OMRON limit switch for X, Y, Z axis |

Command Language | G Code |

Computer Interface | USB |

Software Compatibility | ARTCAM software, (Option: JD Paint, Ucancam, Type3 Software) |

Running Environment Temperature | 0 - 45 Centigrade |

Relative Humidity | 30% - 75% |

* Sign Industry: Acrylic sign making, Wood Sign making, ABS board sign making.

* Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

* The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

* Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti-Bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

* Decorate industry: Acrylic, PVC,MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

UTECH has a professional design and technical team to meet all your needs, and the equipment supports customization.

Before confirming the production order, we will provide the rendering picture and 360-degree panoramic video, so that customers can fully understand the style and structure of the machine, so as to ensure that the actual machine meets the requirements of customers, so as to avoid the discrepancy between the real object and customers' imagination caused by various communication deviations.

UTECH technical support is designed to help you make the most of the machine. A variety of technical files and installation videos will be placed in the U disk and shipped with the machine. Our technical experts can provide online remote support and training, and contact UTECH technical support experts in real-time for remote diagnosis. Door-to-door service is also available.